-

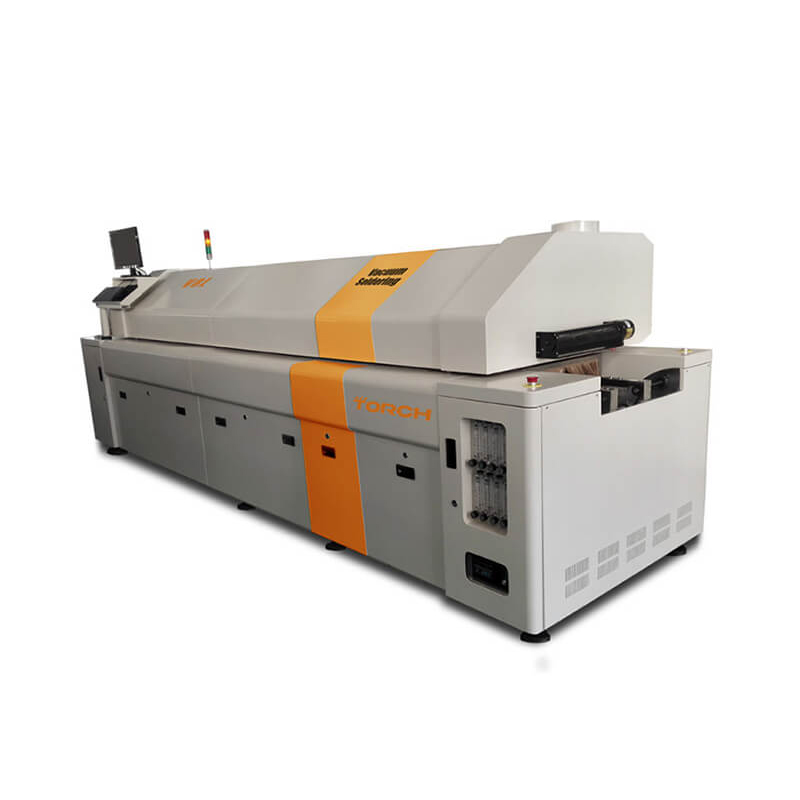

Online Vacuum Reflow Oven VRO945

VRO945 on-line vacuum reflow furnace has the characteristics of large output, low energy consumption, and low nitrogen consumption.

VRO945 is specially designed and optimized for the special needs of vacuum welding packaging of lead frame products in the semiconductor industry and vacuum welding packaging of CLIP products. Taking into account the many problems encountered by customers in the industry, a vacuum furnace has been carefully optimized and designed. -

Nano Silver / Nano Copper Positive Pressure Sintering Furnace SIN100

Nano silver / nano copper positive pressure sintering furnace mainly focuses on mechanical pressure curing. In the selection of pressure equipment, this design uses precision hydraulic control system to achieve high-precision pressure.

Vacuum sealing structure design is adopted in the overall furnace cavity and structure design. During curing, it can be cured in vacuum environment or other inert gas (two or more) protective atmosphere to improve the curing quality of products.

The overall equipment includes: pressure system, vacuum system, heating system, temperature control system, cooling system, etc. -

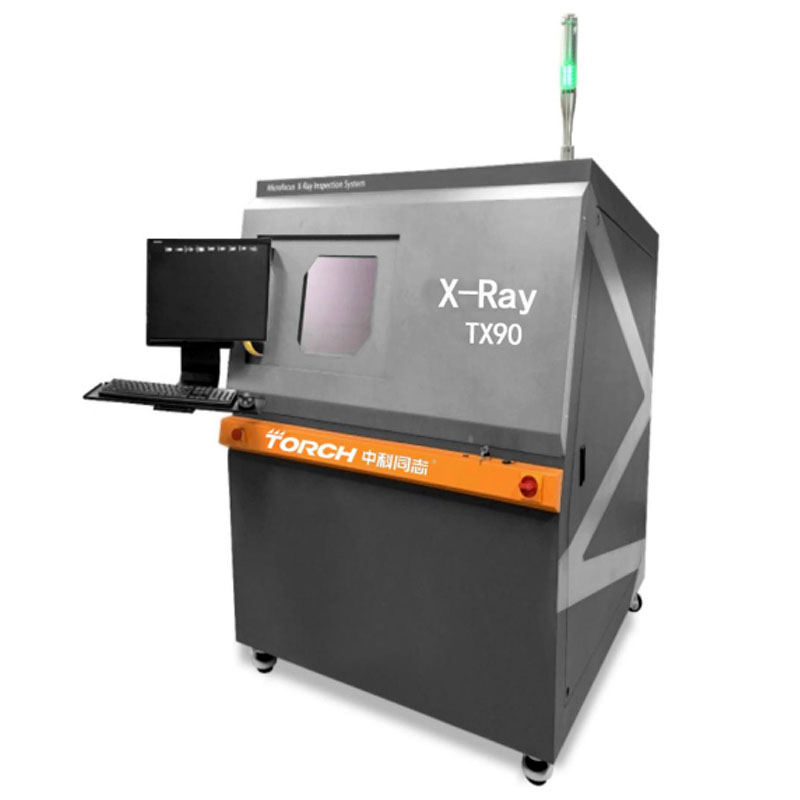

X-ray Detection Equipment TX90

1. The X-ray source adopts closed X-ray tube of Japan Hamamatsu, which is the world's top X-ray source, with long service life and maintenance free.

2. The new generation Iray 5-inch HD digital flat panel detector is used for X-ray receiving.

3. Auto navigation window, where you want to see.

4. 420 * 420mm platform with 15kg load.

5. 3 motion axis linkage system with adjustable speed.

6. The test program can be edited to realize mass automatic test and automatically judge whether it is NG or OK. -

VDO300 Vacuum Exhaust Furnace

VDO300 vacuum exhaust furnace is a new type of vacuum exhaust equipment newly launched by quartz bearing platform technology.

It is used for exhaust and degassing of semiconductor chip, frame, support, solder chip and other products.

Exhaust temperature: The actual maximum exhaust temperature of VDO300 vacuum exhaust furnace is ≤ 300 ℃.

Vacuum degree: Equipped with mechanical oil pump (high-speed rotary vane vacuum pump 40L / M), the maximum vacuum degree is within 30 PA. -

V4D Vacuum Reflow Oven

1. Soldering temperature: The maximum soldering temperature ≥450 ℃.

2. Vacuum rate: The ultimate vacuum ≤10 Pa and the working vacuum is 50Pa-200Pa.

3. Effective soldering area: ≥380mm * 310mm.

4. Furnace height: ≥100mm.

5. Heating method: Infrared radiant heating at the bottom + infrared radiant heating at the top. The hot plate uses a semiconductor-grade graphite platform. The graphite platform is not easy to deform for a long time, and has high thermal conductivity, making the surface temperature of the hot plate more uniform. -

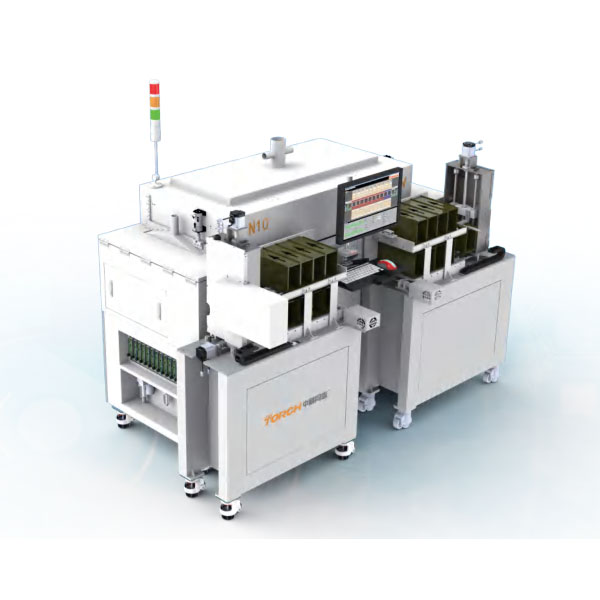

Ten Temperature Zone On-line Nitrogen Reflow Furnace - N10

The nitrogen reflow furnace is filled with nitrogen in the furnace of the reflow furnace in order to block the air inlet in the reflow furnace It prevents oxidation of the chip and frame during reflow soldering. It also prevents oxidation during preheating, welding or cooling.

The nitrogen reflow furnace is mainly used to enhance the welding quality, so that the welding occurs in an environment with little oxygen content (< 50ppm or even lower), which can avoid the oxidation problem of the chip. Therefore, the main problem of nitrogen reflow furnace is to ensure that the lower the oxygen content, the better. -

VPC3i Vacuum Plasma Cleaning Machine

Inline vacuum plasma cleaning machine

Modle No.: VPC3i

Mainly used for plasma surface treatment process in semiconductor enclosure fields such as silicon wafer, glass substrate, ceramic substrate, IC carrier plate, copper lead frame, large-size single-sided substrate power board, IGBT module, MEMS sensor with fixture, microwave device, filter, RF device, etc. -

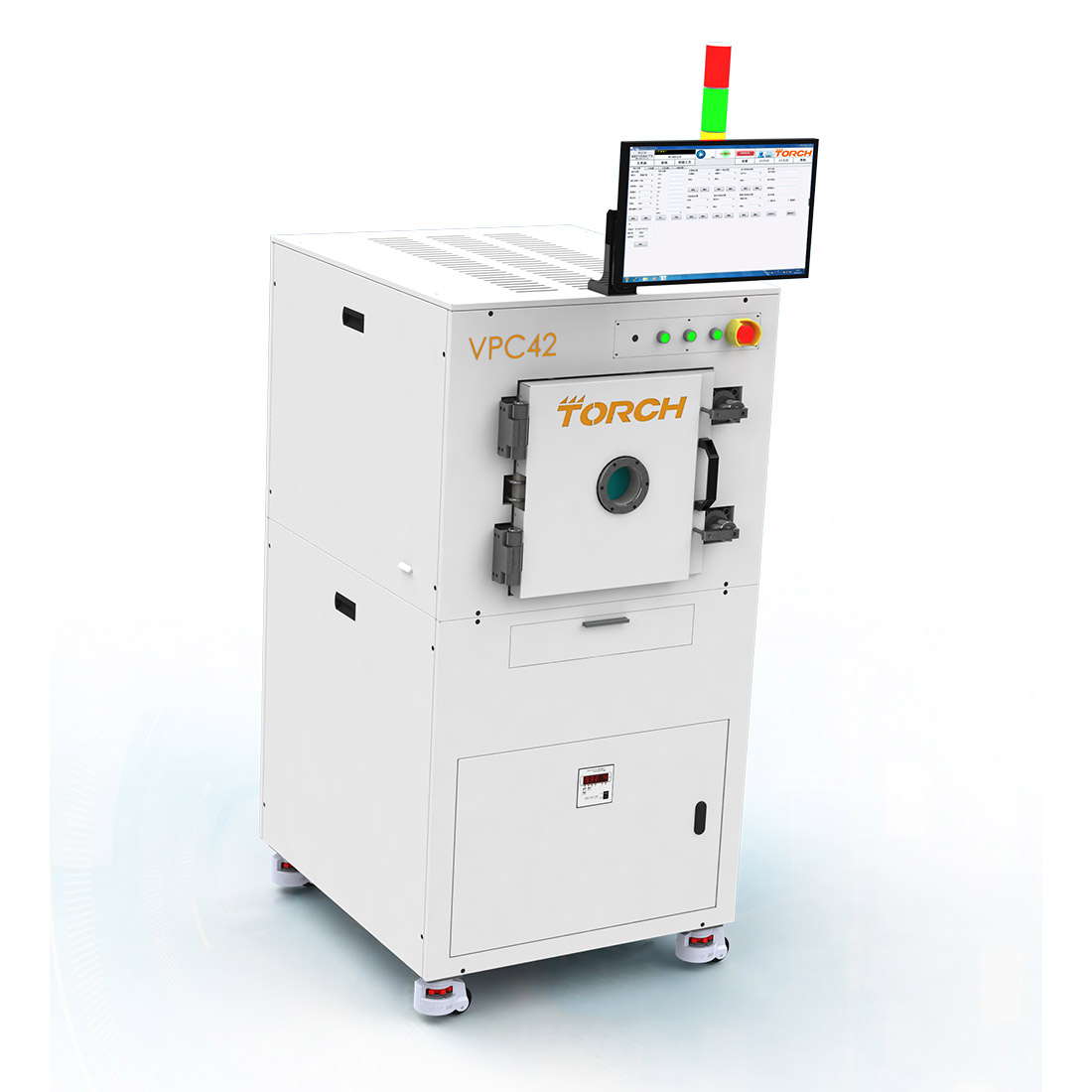

VPC42 Vacuum Plasma Cleaning Machine

Equipment name: Offline vacuum plasma cleaning machine

Modle No.: VPC42

Mainly used for plasma surface treatment process in semiconductor enclosure fields such as silicon wafer, glass substrate, ceramic substrate, IC carrier plate, copper lead frame, large-size single-sided substrate power board, IGBT module, MEMS sensor with fixture, microwave device, filter, RF device, etc. -

Vacuum Annealing Furnace H2S

H2S is a large-size vacuum annealing furnace with a heating plate area of 1100*550mm, which can realize the annealing process for larger-size workpieces or mass annealing process for small-size workpieces. It has a wide range of adaptability and is suitable for various production needs of customers.

-

Vacuum Welding Furnace H3

H3 vacuum welding furnace is the latest vacuum welding equipment introduced by our company. It is suitable for mass production of high-power devices, such as IGBT module, power control board, high-power LED and other devices with higher requirements for welding, which can effectively reduce the void rate of the device welding surface.

-

Large-scale Vacuum Soldering System H5/H6

Brief Introduction: the introduction of H5.

Application Fields: IGBT module, MEMS packaging, high power electronics packaging, photoelectric device packaging, hermetic packaging etc. -

RS Series Vacuum Reflow Oven RS220

1. TORCH promotes a new Vacuum Reflow Oven in RS series which is the third generation of its small Vacuum Reflow Oven. It especially designed for the fields in small batch production, R&D and functional materails test, etc.

RS Series Vacuum Reflow Oven is heated in Vacuum environment to realize holesless soldering, can fulfill the test requirement from R&D department and production requirement of small batch. -

RS Series Vacuum Reflow Oven RS160

1. TORCH promotes a new Vacuum Reflow Oven in RS series which is the third generation of its small Vacuum Reflow Oven. It especially designed for the fields in small batch production, R&D and functional materails test, etc.

RS Series Vacuum Reflow Oven is heated in Vacuum environment to realize holesless soldering, can fulfill the test requirement from R&D department and production requirement of small batch. -

RS Series Vacuum Reflow Oven RS110

1. TORCH promotes a new Vacuum Reflow Oven in RS series which is the third generation of its small Vacuum Reflow Oven. It especially designed for the fields in small batch production, R&D and functional materails test, etc.

RS Series Vacuum Reflow Oven is heated in Vacuum environment to realize holesless soldering, can fulfill the test requirement from R&D department and production requirement of small batch. -

Compact Vacuum Reflow Oven V2

V2 vacuum adopts the temperature control technology patented by comrades technology, and the temperature control accuracy is ± 1 ℃.

V2 vacuum temperature curve can set up to 40 sections of temperature, and is equipped with 6 sets of PID settings to control the temperature more precisely, so as to ensure the welding consistency and reliability. Temperature control is lagging control, and PID control has the function of advance adjustment, which can improve the accuracy and stability of temperature control. -

Compact Vacuum Reflow Oven V3/V4/V5

1. High quality, anti-oxidation welding.

2. 4 temperatures test.

3. Special for military, aviation, aerospace and other high-end products manufacture.

4. Temperature capable up to 450℃.

5. Vacuum capable up to 10-6 mbar.

6. aerospace aluminum overall material, high-strength, high-security. -

High Vacuum Reflow Oven V3HV

1. The name V3/V4/V5 is called according Vacuum, means professional industrial Vacuum reflow oven.

2. Why chose Vacuum reflow oven? Recently, the main welding tool is soldering iron, reflow oven, wave solder machine or other welding machine, and later update to Nitrogen reflow oven. But some welding, need high requirement of welding, like material testing, Chip packing, Power equipment, Automotive products, Train control, Plane system, aerospace system, which need avoid the Empty and oxidation of welding. Vacuum reflow oven is the unique choice to reduce empty and oxidation. Vacuum reflow oven can make sure high quality of welding. Vacuum welding is the new technology in Germany, Japan, USA. -

Vacuum Eutectic Furnace V4A

1. Welding temperature: The actual maximum welding temperature of Vacuum Eutectic Furnace V4A is ≥600℃.

2. Vacuum degree: ultimate vacuum degree ≤10 Pa, working vacuum 50Pa-200Pa.

3. Effective welding area: ≥380mm*310mm.

4. Furnace height: ≥100mm, customized for special height.

5. Heating method: using bottom infrared radiation heating + top infrared radiation heating, the heating plate adopts semiconductor grade silicon carbide graphite flat. The silicon carbide graphite platform is not easy to deform after long-term use, and has high thermal conductivity, which makes the surface temperature of the hot plate more uniform. -

High Temperature Vacuum Sintering Furnace V4HT

1. The name V3/V4/V5 is called according Vacuum, means professional industrial Vacuum reflow oven.

2. Why chose Vacuum reflow oven? Recently, the main welding tool is soldering iron, reflow oven, wave solder machine or other welding machine, and later update to Nitrogen reflow oven. But some welding, need high requirement of welding, like material testing, Chip packing, Power equipment, Automotive products, Train control, Plane system, aerospace system, which need avoid the Empty and oxidation of welding. Vacuum reflow oven is the unique choice to reduce empty and oxidation. Vacuum reflow oven can make sure high quality of welding. Vacuum welding is the new technology in Germany, Japan, USA. -

Channel Type Vacuum Reflow Soldering System V8L

1. Significantly reduce the welding bubbles in the solder, making the void rate as low as 1-2%.

2. Improve the electrical performance of the product and the welding joints, effectively improving the reliability of the welding point and the welding quality.

3. It can be used for double-sided welding of PCB, suitable for mass production, and can be continuously put into the production line. The production cycle is controlled at an average of 30-60S. -

Online Vacuum Welding Furnace V8S

1. V8S on-line vacuum welding furnace has the characteristics of large output, low energy consumption, low nitrogen consumption, and small footprint.

2. V8S is specially designed and optimized for the requirements of vacuum welding and packaging for lead frame products and power devices in the semiconductor industry. Taking into account the many problems encountered by customers in the industry, we have carefully optimized the design and completed this vacuum furnace. -

VDF Series Vacuum Degassing Furnace VDF200/500

The VDF series vacuum degassing furnace is a commonly used equipment in the fields of MEMS chips, infrared chips, and high vacuum packaging chips. It is mainly used for device degassing, material degassing, and packaging process

2. Clean environment: high-purity quartz glass is used in the liner of the equipment to ensure that no foreign matter is generated during the degassing process. -

Gas Phase Vacuum Reflow Soldering Machine VP650

1. Gas phase high vacuum vacuum reflow soldering machine is a professional industrial-grade high vacuum vacuum reflow soldering machine.

2. Why chose Vacuum reflow oven? Recently, the main welding tool is soldering iron, reflow oven, wave solder machine or other welding machine, and later update to Nitrogen reflow oven. But some welding, need high requirement of welding, like material testing, Chip packing, Power equipment, Automotive products, Train control, Plane system, aerospace system, which need avoid the Empty and oxidation of welding. Vacuum reflow oven is the unique choice to reduce empty and oxidation. Vacuum reflow oven can make sure high quality of welding. Vacuum welding is the new technology in Germany, Japan, USA.