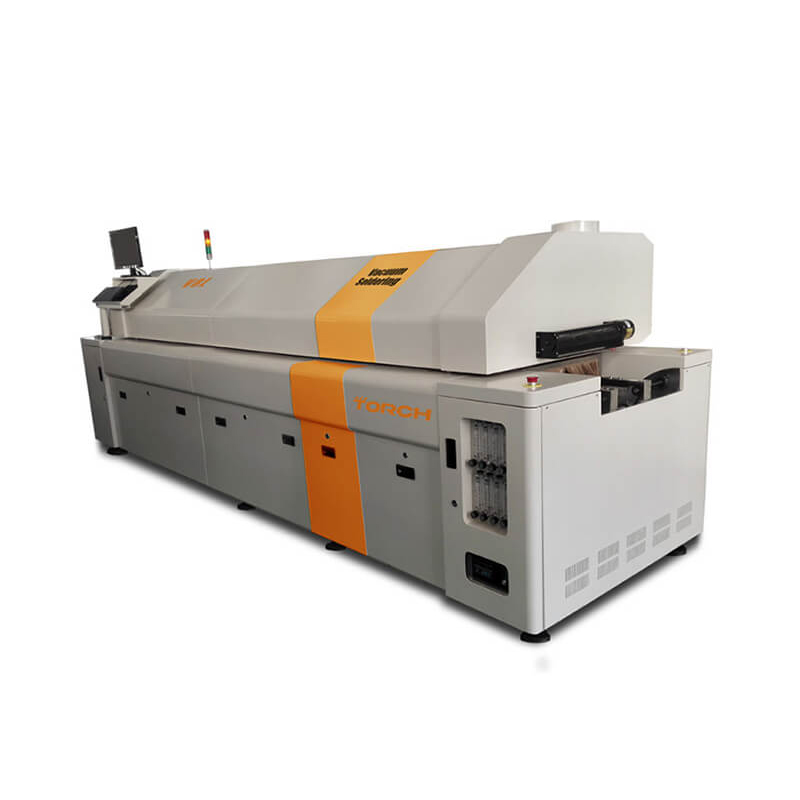

Online Vacuum Welding Furnace V8S

Description of Online Vacuum Welding Furnace V8S:

1. V8S on-line vacuum welding furnace has the characteristics of large output, low energy consumption, low nitrogen consumption, and small footprint.

2. V8S is specially designed and optimized for the requirements of vacuum welding and packaging for lead frame products and power devices in the semiconductor industry. Taking into account the many problems encountered by customers in the industry, we have carefully optimized the design and completed this vacuum furnace.

1). Large output: For example, production efficiency for a 72mm wide lead frame can reach 240-300 pieces/hour; a 120mm wide power module can reach 130-200 pieces/hour.

2). Low energy consumption: starting power of the whole machine: 18KW; average operating power of the whole machine: 8KW.

3). Low nitrogen consumption: nitrogen consumption only accounts for 1/5 of other similar vacuum furnace products.

4). Overall dimensions: 2600*1000*1300mm

Functions:

1. Meet the soldering requirements of various solders (≤450°C): For example: SAC305 solder paste; Sn63Pb37 solder paste; Sn90Sb10 solder paste; In97Ag3 solder paste; In52Sn48 solder paste and other various component solder pastes.

2. V8S welding void rate: pad void rate: <1%. Single void rate: 2%. Different welding materials and atmospheres have an impact on welding. The current data is based on comprehensive data after customer testing. Specific to different welding products, this data will be different.

3. V8S supports a nitrogen atmosphere working environment to meet a variety of welding processes.

4. The V8S vacuum reflow soldering machine is equipped with a software control system, modular design settings, and a simple and easy-to-understand operation interface.

5. The equipment does not need to be calibrated, and there will be no extra calibration costs.

Equipment Configuration:

| Name | Configuration | Quantity |

| Temperature control system | Standard (20 sets of temperature-controlled thermocouples) | One set |

| Temperature measurement system | Standard (4 sets of thermocouples for temperature measurement) | Two set |

| Vacuum system | Standard | One set |

| Industrial computer | Siemens Industrial Computer | 1台 |

| Heating platform | Alloy heating platform | Two set |

| Water cooling system (including industrial water chillers) | Standard (water chiller, water cooling pipeline and interface) | One set |

| Nitrogen protection system | Standard (nitrogen gas pipeline and interface) | One set |

| Flux recovery system | Standard (flux cooling, filtering system and interface) | One set |

| Vacuum reflow soldering control system | Standard (control software) | One set |

Technical Parameters:

| Maximum heating zone length requirements | 320*160mm |

| heating method | Infrared metal alloy heating |

| Furnace height | 10mm |

| Oxygen content | 100PPM |

| Maximum temperature | 450℃ |

| Minimum vacuum value | 50Pa |

| Vacuum pump pumping rate | (50Hz) 3L/S |

| Cooling Method | Water cooling |

| Temperature control accuracy | 0.1℃Max |

Actual Data of Standard Machine:

20pa: 12min

50pa: 100S

100pa: 15S

200pa: 14S

500pa: 12S