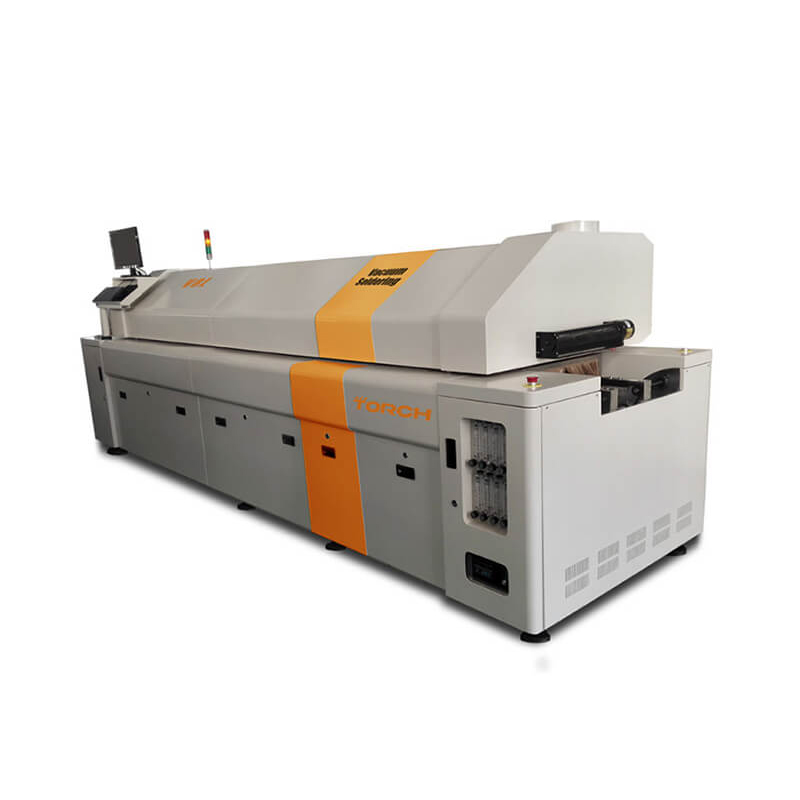

High Temperature Vacuum Sintering Furnace V4HT

Introduction:

1. The name V3/V4/V5 is called according Vacuum, means professional industrial Vacuum reflow oven.

2. Why chose Vacuum reflow oven? Recently, the main welding tool is soldering iron, reflow oven, wave solder machine or other welding machine, and later update to Nitrogen reflow oven. But some welding, need high requirement of welding, like material testing, Chip packing, Power equipment, Automotive products, Train control, Plane system, aerospace system, which need avoid the Empty and oxidation of welding. Vacuum reflow oven is the unique choice to reduce empty and oxidation. Vacuum reflow oven can make sure high quality of welding. Vacuum welding is the new technology in Germany, Japan, USA.

3. Industry application: V series high vacuum reflow soldering machine is an ideal choice for R&D, process research and development, and low to high capacity production. It is the choice for R&D and production in military enterprises, research institutes, universities, aerospace and other fields.

4. Application: Mainly used for defect-free soldering of chips and substrates, tube shell and cover plate, and perfect solderless soldering, such as IGBT package, solder paste process, laser diode package process, optical communication device soldering, mixing Integrated circuit package, tube shell and cover plate package, MEMS and vacuum package.

5. Vacuum reflow has become an essential equipment for high-end manufacturing of military and industrial enterprises, aviation and aerospace in developed countries such as Europe and the United States, and has been widely used in chip packaging and electronic soldering.

Features:

1. Vacuum welding environment, can be up to 10-3mba

2. Low active flux welding environment.

3. Touch screen control and professional software, get perfect operation.

4. 40 sections programmed temperature control system, can set perfect welding profile carve.

5. Temperature settings can be adjusted, which can set the welding materials technology curve that is much closer to perfect the process.

6. Water-cooling technology achieves the industry's fastest cooling effect (standard).

7. 4 temperature testing. Realize the measurement of temperature uniform in welding zone.

8. Choose formic acid, nitrogen or other inert gases to meet the welding requirements of special processes.

9. Patent design in online real video system, can take video of every process and provide good reference for quality tracking, perfect data support in researching of welding and test in materials.

10. Highest temperature is 1100 (higher optional), which can meet all the requirements of the soldering process.

11. View window on the cover.

12. 8 safety system monitor and protect system (Overtemperature protection, The temperature security protection, air pressure protection, water pressure protection, safety operation protection, water cool protection, liquid volume protection, power off protection).

Standard:

1. One host.

2. One industrial-grade touch screen computer.

3. One set of temperature controller.

4. One set of pressure controllers.

5. One set of closed-loop water cooling system.

6. One set of four-way temperature measurement module.

7. One set of vacuum pressure transmitter.

8. One set of inert gas or nitrogen control valve.

9. One set of water tanks.

10. One set of chillers.

11. Configure molecular pump.

Technical Parameters

| Model | V4HT |

| Heating plate area | 350*280mm |

| Furnace height | 40mm(Other heights optional) |

| Data interface | Serial port /USB port |

| Control system | 40 stage temperature control + vacuum pressure control |

| Temperature curve | Can store several 40 segment temperature curve |

| Voltage | 220V 25-50A |

| Rated power | 11kW |

| Actual Power | 8KW (No vacuum pump) 10KW (Formulated molecular pump) |

| Dimension | 900*1100*1300mm |

| Weight | 390KG |

| Vacuum degree | 10-3pa |

| Maximum temperature | 1100℃ |

| Heating rate | 120-300℃/minute |

| Cooling rate | 120℃/minute |