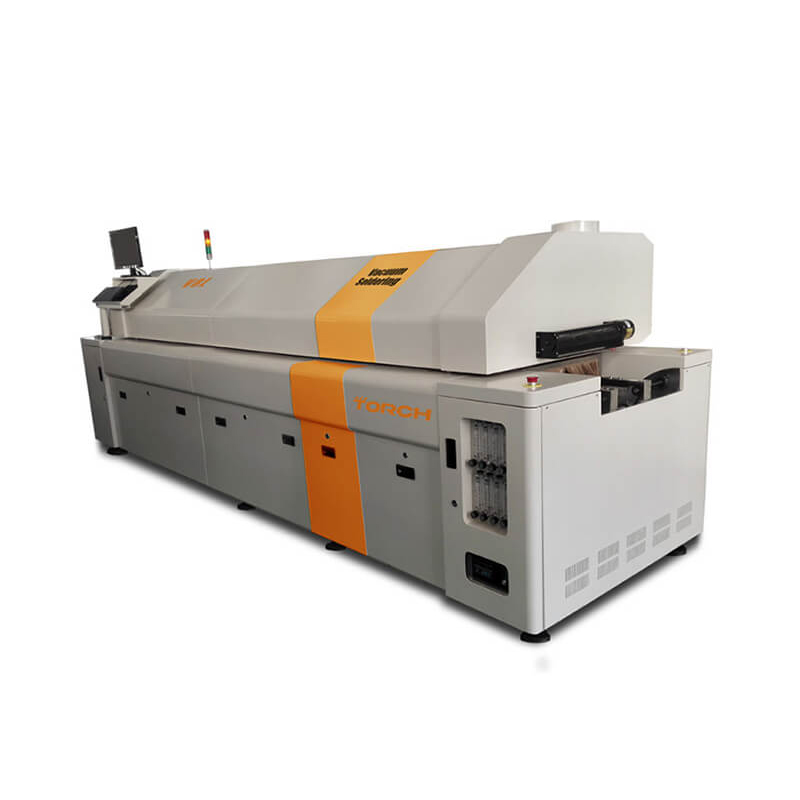

Channel Type Vacuum Reflow Soldering System V8L

Technical Data of Vacuum Reflow Soldering System V8:

1. Significantly reduce the welding bubbles in the solder, making the void rate as low as 1-2%.

2. Improve the electrical performance of the product and the welding joints, effectively improving the reliability of the welding point and the welding quality.

3. It can be used for double-sided welding of PCB, suitable for mass production, and can be continuously put into the production line. The production cycle is controlled at an average of 30-60S.

4. The degree of vacuum, vacuum holding time, deflation time, vacuum rate, etc. can be set freely.

5. The circuit board with aluminum heat sink can be welded.

6. Low power consumption and high heat insulation design based on the concept of environmental protection. The case temperature does not exceed 40 degrees.

7. High-efficiency and large-capacity flux recovery device.

8. Use integrated oxygen sensor technology to ensure precise control of oxygen content, and real-time/continuous monitoring of residual oxygen content in the furnace.

9. The equipment can be used as an ordinary nitrogen or air furnace at the same time.

Technical Data of Vacuum Reflow Soldering System V8L

| (Required) | Technical specifications | model: V8L |

| Actual index value | ||

| Actual index value | length | MAX 400mm |

| width | MAX 450mm | |

| height | MAX 30mm | |

| Performance parameter | heating method | Hot air heating |

| Speed adjustable range | ≥20cm/min | |

| Max. heating temperature | MAX 350℃ | |

| heating temperature | <200ppm | |

| Heating rate range | 1-3℃/s | |

| Heating rate range | 1-3℃/s | |

| The temperature of the baked product | 80℃ | |

| Heating rate range | ±4℃ | |

| Number of equipment temperature zones (heating) | 8+1 | |

| Number of equipment temperature zones (Cooling) | 2 | |

| Warm-up time (heating time) | According to the specific requirements of the process | |

| Oil pump meets the demand of clean room/class 10,000 | Class 10,000 | |

| Class 10,000 | ≤2mbar | |

| Dimension/Weight | Dimension (m) | 6.3m(L)*1.55m(L)*1.7m(H) |

| Weight (Kg) | 1600kg | |

| Power | Voltage | 380V |

| Frequency | 50Hz | |

| Power Consumption | Maximum power 32KW Average power 10KW |

|

| UPS | Optional | |

| Forming Gas/N2 | Connector Diameter | 10mm |

| Pressure | 0.3MPa-0.6MPa | |

| Nitrogen consumption | 300L/min | |

| Flow Rate | 80psi (0.5Mpa, gas flow rate 80L/M) | |

| Compressed Air | Connector Diameter | 10mm |

| Pressure | 0.3MPa-0.6MPa | |

| Flow Rate | 80psi (0.5Mpa, gas flow rate 80L/M) | |

| Exhaust | Exhaust Flow | MAX 8L/s |

| Cooling Water | Connector Diameter | 10mm |

| Flow Rate | Instantaneous maximum 18L/s | |

| Instantaneous maximum | Delivery cycle/week | 60 days |

| Can the delivery be delayed when the on-site installation conditions are not met | Yes | |

| Technical support, training requirements | The response time for troubleshooting at the site is within 48 hours, and training is included. | Arrive at the site for 24 hours, and installation training is included. |