Compact Vacuum Reflow Oven V2

Unique feature:

1. Welding temperature: actual maximum welding temperature of V2 vacuum eutectic furnace ≥ 450 ℃.

2. Vacuum degree: limit vacuum degree ≤ 3 Pa working vacuum 10-200 PA.

3. Effective welding area: ≥ 210mm * 200mm.

4. Furnace height: ≥ 100mm.

5. Heating mode: bottom infrared radiation heating is adopted, and the wafer support platform is semiconductor grade silicon carbide coated graphite platform.

6. Temperature uniformity: within the effective welding area ≤± 1%.

7. Heating rate: the maximum heating rate is 120-240 ℃ / min.

8. Cooling rate: the maximum cooling rate is 60-120 ℃ / min.

9. Void ratio: During the vacuum eutectic welding of V2 type vacuum eutectic furnace, the cavity rate can be controlled below 2% after a large number of customer verification.

10. Optional positive pressure module:

The equipment can be equipped with positive pressure module ≤ 0.3MPa, which can meet the process requirements of positive pressure and negative pressure. Positive pressure process can be effectively solved The problem of displacement of micro devices in the welding process and the problem of flux splashing in the solder paste process are solved.

11. Temperature control system and temperature measurement system

V2 vacuum adopts the temperature control technology patented by comrades technology, and the temperature control accuracy is ± 1 ℃.

V2 vacuum temperature curve can set up to 40 sections of temperature, and is equipped with 6 sets of PID settings to control the temperature more precisely, so as to ensure the welding consistency and reliability. Temperature control is lagging control, and PID control has the function of advance adjustment, which can improve the accuracy and stability of temperature control.

V2 type vacuum eutectic furnace cavity is equipped with two groups of flexible temperature measuring thermocouples with patented technology. When the equipment works, it can feedback the temperature of any position in the cavity in real time, and display the temperature curve of temperature measurement in real time in the control software, so as to better ensure the temperature control of the welding area and provide support for obtaining good process curve.

12. Chamber atmosphere environment

V2 type vacuum eutectic furnace can be filled with nitrogen inert gas to assist welding, and meet the reduction atmosphere process of formic acid, nitrogen hydrogen mixture (5% hydrogen 95% nitrogen). The process atmosphere can be precisely controlled by time or MFC mass flowmeter to ensure the consistency of each set process. The equipment is equipped with a closed exhaust channel and filter system, which can be treated and discharged through the exhaust channel to ensure the normal use of the equipment. It can meet the requirement of welding without flux.

13. V2 vacuum eutectic furnace configuration software control system:

13.1. the software control system is based on the windows operating system and is easy to operate.

13.2. the process can be programmed by temperature, time, pressure, vacuum and other process conditions, and the software process can automatically control the whole process.

13.3. there are infinite process actions of process curve programming, which meet the requirements of complex process.

13.4. the control system shall meet various welding process curves, and shall be set, modified, stored and transferred according to different processes.

13.5. the control system has its own analysis function, which can analyze the process curve and determine the information of temperature rise, constant temperature, temperature drop, etc.

13.6. the software control system automatically records the welding process, temperature control and temperature measurement curve in real time, ensures the traceability of the device process, and automatically stores it in the corresponding directory according to the process working time.

14. V2 vacuum eutectic furnace adopts closed cavity structure to ensure the reliability of long-term use. When the upper cover is closed in the use process, it will not cause device displacement and avoid the impact of device vibration on the welding quality. The single chamber process can meet the requirements of heating and cooling at the same time.

15. V2 type vacuum eutectic furnace, with windows on the top cover, can observe the sintering process of the device through the microscope. The upper cover is automatically lifted and lowered, and other operation software is automatically controlled except for manual parts.

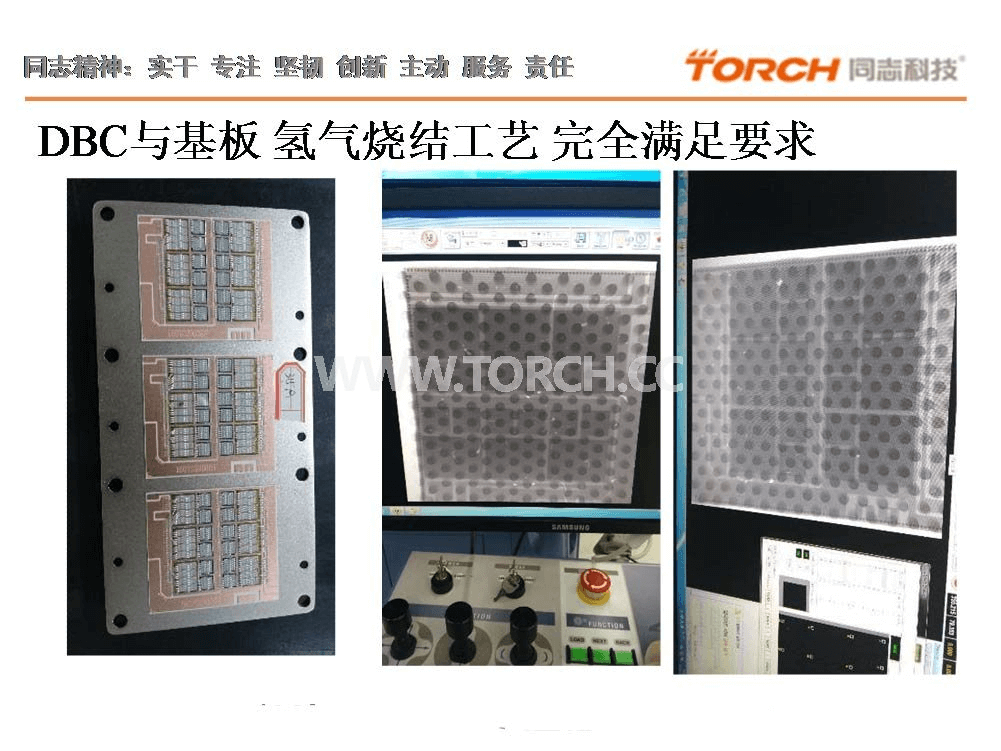

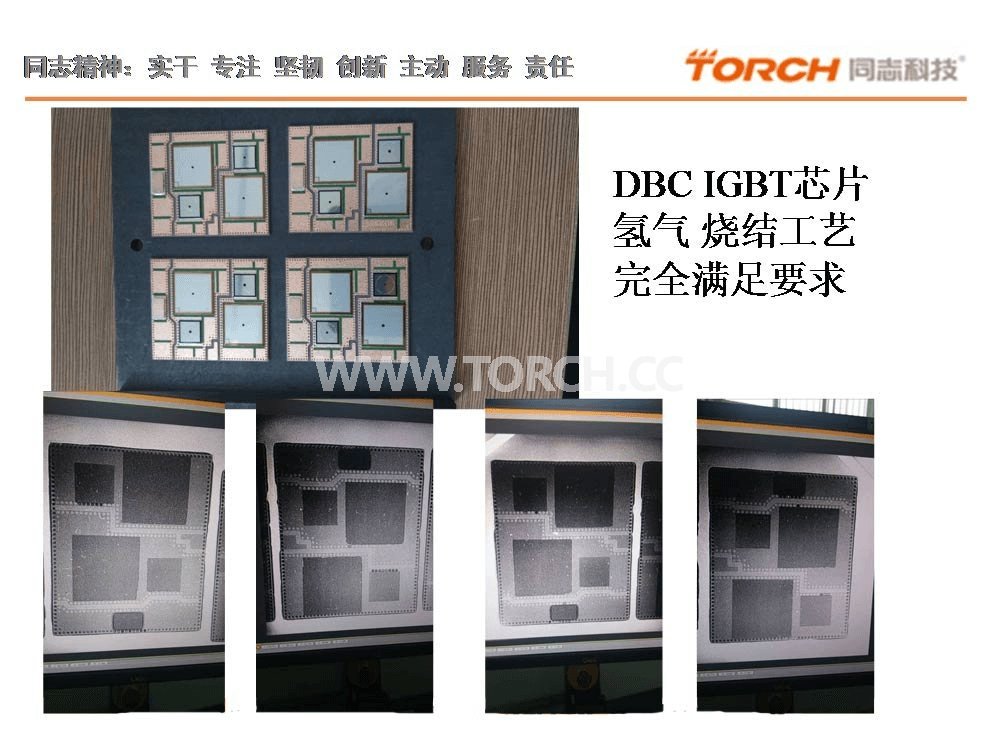

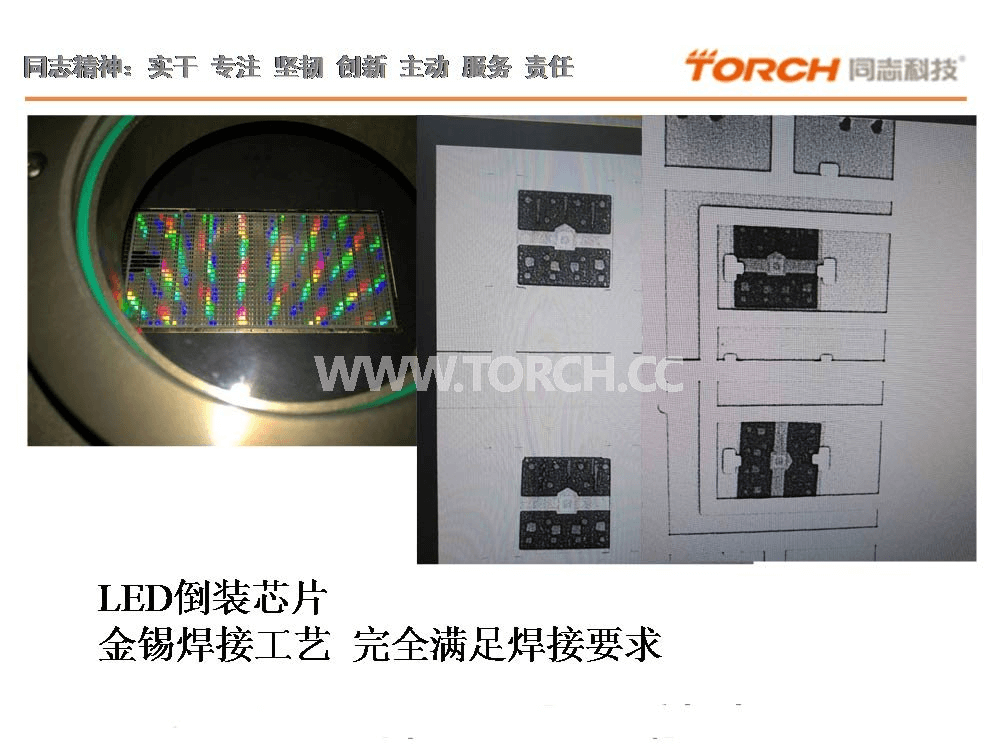

Some customer test pictures (pictures are customer products, please do not reprint)

Accessories list

| No | Name of spare parts | Configuration | Quantity | |

| 1 | Main machine of vacuum eutectic furnace | Standard configuration | 1set | |

| 2 | Temperature control system (TORCH) | Standard configuration | 1set | |

| 3 | Temperature measurement system (TORCH) | Standard configuration | 2set | |

| 4 | vacuum system | Vacuum pump (mechanical oil pump) | Standard configuration | 1set |

| Vacuum pump (mechanical dry pump) | Optional | $3571-$7857/set | ||