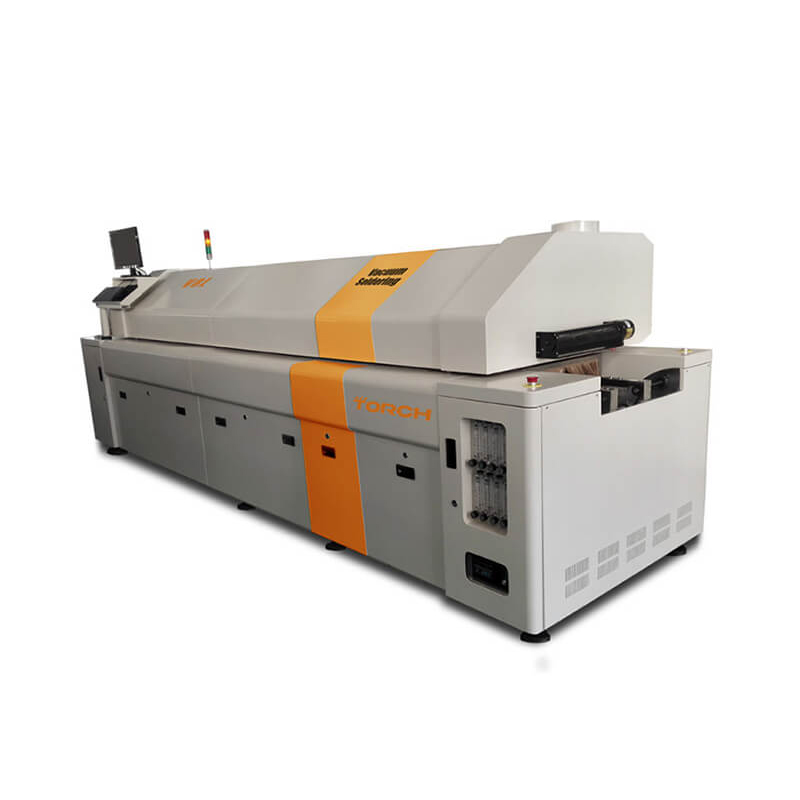

Compact Vacuum Reflow Oven V3/V4/V5

Unique feature:

1. High quality, anti-oxidation welding.

2. 4 temperatures test.

3. Special for military, aviation, aerospace and other high-end products manufacture.

4. Temperature capable up to 450℃.

5. Vacuum capable up to 10-6 mbar.

6. Aerospace aluminum overall material, high-strength, high-security.

Product introduction:

1. V3/V4/V5 is called from Vacuum, professional industrial Vacuum reflow oven.

2. Why choose Vacuum reflow oven? Nowadays, the main welding tool is soldering iron, reflow oven, wave soldering machine and other welding machine, even update to Nitrogen reflow oven. As to some welding area, which need high requirement of welding, like material testing, Chip packing, Power equipment, Automotive products, Train control, Plane system, aerospace system, which prevent Empty and oxidation of welding. Vacuum reflow oven is best choice to reduce empty and oxidation. Vacuum reflow oven can make sure high quality of welding. Vacuum welding become new technology in Germany, Japan, USA.

3. Application: Military enterprise, Research institutes, University, Aerospace, and it’s the best choice for R&D, Process research.

4. Application of field: suit for no defect welding and perfect no flux welding in Chip and PCB Board, cover and board, like IGBT package, solder paste process, laser diode package, IC package, MEMS and vacuum package.

5. Vacuum reflow oven is necessary equipment in Military enterprise, Aerospace in USA, European, also get university application in Chip package, electronic welding.

Feature of the vacuum reflow oven:

1. Vacuum welding environment, can be up to 10-3mba (10-6mba is optional if you choose molecular pump).

2. For fluxless and void-free soldering.

3. Touch screen control and professional software, perfect operation.

4. 40 sections programmed temperature control system, perfect welding profile carve.

5. Touch screen control temperature model, pull the curve by hand.

6. Unique water cooling system.

7. 4 temperature tests to measure temperature uniform in welding zone. Supply professional reference in process test.

8. Formic acid, nitrogen or other Inert gas suitable for welding process.

9. Patent design of online operation video system, take video for every process and provide good evidence for quality tracking, sufficient data support in welding research and materials experience.

10. Highest temperature: 450℃ (higher temperature is optional), meet all welding requirements.

11. Viewing window equipped with the machine.

12. 8 safety system monitor and protect system (Over temperature protection, security protection, air pressure protection, water pressure protection, safety operation protection, water cooling protection, liquid volume protection, power off protection).

Technical parameter:

| Model No | V3 | V4 | V5 |

| process chamber size | 280mm*260mm | 380mm*310mm | 500mm*380mm |

| Size | 780*850*1215mm | 780*900*1215mm | 950*900*1215mm |

| Rated Power | 9KW | 11KW | 13KW |

| Real power | 6KW (no molecular pump) | 8KW (no molecular pump) | 10KW (no molecular pump |

| 8KW (configure molecular pump) | 10KW (configure molecular pump) | 12KW (configure molecular pump) | |

| Height of oven | 80mm (other height is optional) | ||

| Temperature range | up to 350-450℃ | ||

| Interface | serial port /USB | ||

| Control way | 40 sections temperature control + vacuum pressure control | ||

| Temperature curve | Can save 40 sections temperature curve | ||

| Power supply | AC220V, 25-5A | ||

| Weight | 340KG | 390KG | 450KG |

| Max temperature rising speed | 300/min | 220/min | 160/min |

| Max temperature reduce speed | 90k/min, 130k/min (Height of oven is 400mm) | 80k/min, 110k/min (Height of oven is 400mm) | 70k/min, 100k/min (Height of oven is 400mm) |

Standard configuration:

| Main body | V3/V4/V5 |

| V-TSC | Torch screen computer |

| V-TC | 4 thermocouple to measure on device, for external measurement tool |

| V-PC | Pressure control |

| V-WC | Closed loop water cooling system |

| V-TTM | 4 real temperature test mode |

| V-VPT | Vacuu m pressure transfer |

| V-IG | Inert gas or nitrogen control |

| V-WB | Water box |

| V-Cool water machine | Cool water machine |

Options and accessories:

| V-MPC | Chemcial resistant diaphragm pump for vacuum up to 10 mbar with manometer |

| V-RVP | Rotary vane pump for vacuum up to 10-3mbar |

| V-HVP | Turbomolecular pump system for vacuum up to 10-6mbar |

| V-FA | Formic acid module (integrated in machine) |

| V-PS | 110V power supply |