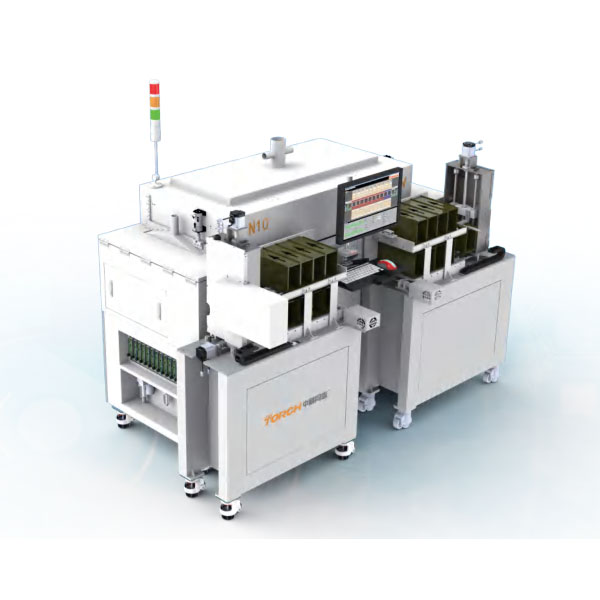

V4D Vacuum Reflow Oven

Ⅰ. Product information:

1. Soldering temperature: The maximum soldering temperature ≥450 ℃.

2. Vacuum rate: The ultimate vacuum ≤10 Pa and the working vacuum is 50Pa-200Pa.

3. Effective soldering area: ≥380mm * 310mm.

4. Furnace height: ≥100mm.

5. Heating method: Infrared radiant heating at the bottom + infrared radiant heating at the top. The hot plate uses a semiconductor-grade graphite platform. The graphite platform is not easy to deform for a long time, and has high thermal conductivity, making the surface temperature of the hot plate more uniform.

6. Temperature uniformity: within the effective soldering area ≤ ± 2%.

7. Heating rate: The maximum heating rate of SiC graphite heating platform is 120℃/min.

V4D vacuum eutectic furnace is equipped with upper heating to improve the heating efficiency while making the platform temperature more uniform and improving the soldering consistency and quality.

8. Cooling rate: The maximum cooling rate is 120 ℃/ min (the highest temperature of no-load is in the range of -200℃).

SiC Graphite heating platform: Air cooling + water cooling combined cooling method is used to achieve rapid cooling of the hot plate, increase the cooling rate, and realize that the temperature difference during the cooling process is too large, resulting in poor device sintering.

9. Meet the soldering requirements of various solders (≤450℃).

For example: In97Ag3, In52Sn48, Au80Sn20, SAC305, Sn90Sb10, Sn63Pb37, Sn62Pb36Ag2 and other pre-formed soldering pads (flux-free eutectic welding) and solder pastes of various compositions.

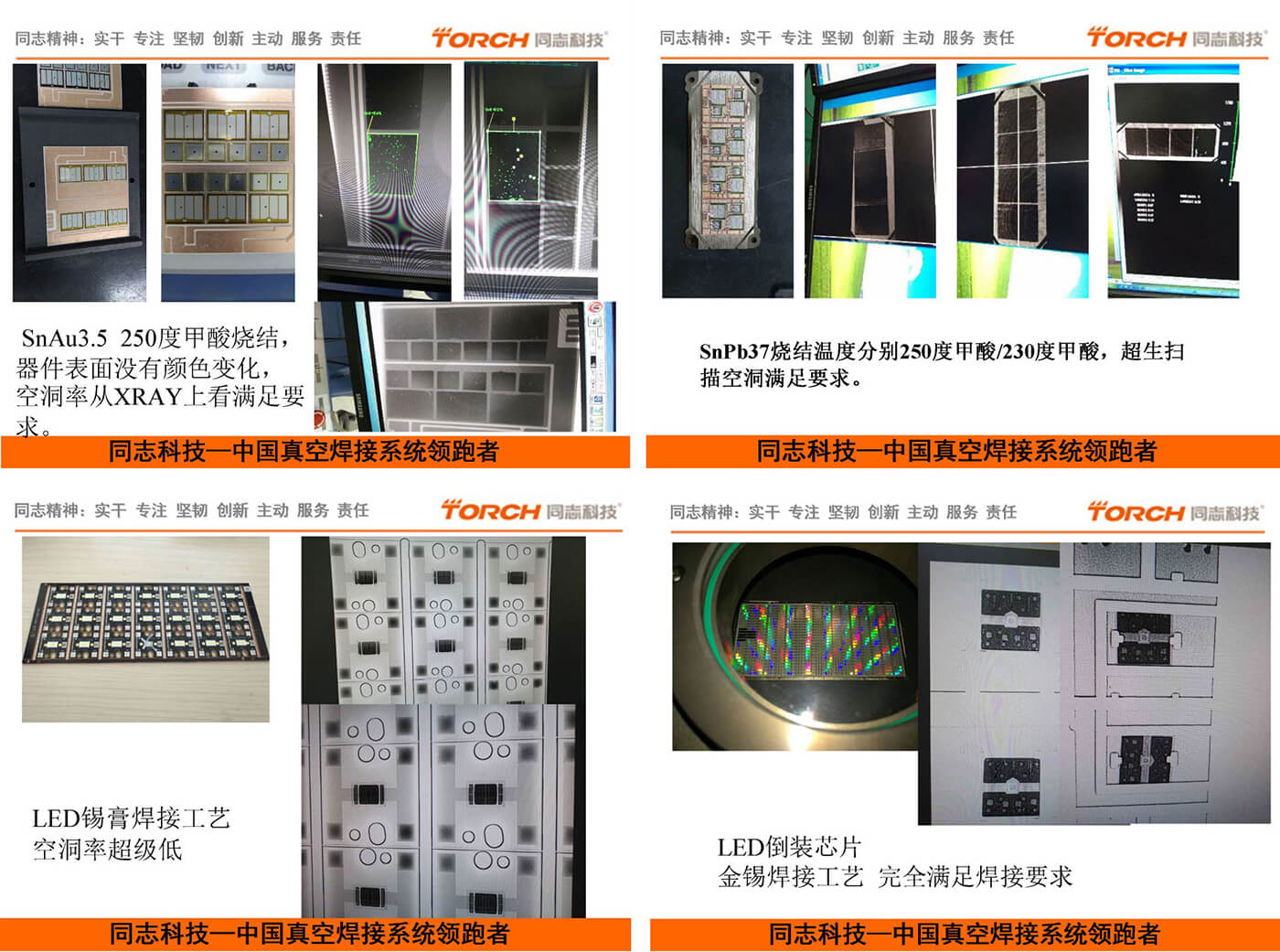

10. Soldering void ratio:

V4D vacuum sintering furnace has been tested by a large number of customers when soldering, and the void ratio can be controlled below 3%.

11. Optional positive pressure module:

The equipment can be equipped with positive pressure module ≤0.3Mpa, which can meet the requirements of positive pressure and negative pressure processes. Positive pressure process can effectively solve.

The problem of displacement of small devices during the soldering process (MiniLED, MicroLED, etc.), and solving the problem of flux splash in the solder paste process (lead frame products).

12. Temperature control system and temperature measurement system.

12.1 V4D vacuum sintering furnace adopts the patented temperature control technology of Beijing Torch Co,. Ltd, the temperature control accuracy is within ±1℃.

12.2 The temperature curve of V4D vacuum sintering furnace can set up to 40 stages of temperature, and is configured with 6 sets of PID settings to control the temperature more accurately and ensure the consistency and reliability of soldering. The temperature control belongs to the lag control, and the PID control has the function of advance adjustment, which can improve the temperature control accuracy and stability.

12.3 V4D vacuum sintering furnace cavity is equipped with two groups of flexible temperature measuring thermocouples with patented of Beijing Torch Co., Ltd. When the equipment is working, it can feedback the temperature anywhere in the cavity in real time, and display the temperature measurement temperature curve in the control software in real time. Good temperature control in the welding area can provide support for obtaining good process curves.

13. cavity atmosphere environment

V4D vacuum sintering furnace can be filled with nitrogen inert gas to assist welding, and at the same time meet the reducing atmosphere process of formic acid, nitrogen and hydrogen mixed gas (5% hydrogen 95% nitrogen). The process atmosphere can be precisely controlled by time or by the MFC mass flow meter to ensure the consistency of each set of process completion. The equipment comes with a closed exhaust gas exhaust channel and filter system, which is processed and discharged through the exhaust channel to

14. V4D vacuum eutectic furnace configur software control system:

14.1 The software control system is based on the Windows operating system and is easy to operate.

14.2 Process programming can be performed through temperature, time, pressure, vacuum and other process conditions. The software process automatically controls the entire process.

14.3 Process curve programming has an infinite number of process actions to meet the requirements of complex processes.

14.4 The control system meets various welding process curves, and can be set, modified, stored, and called according to different processes.

14.5 The control system comes with an analysis function, which can analyze the process curve and determine the information such as temperature rise, constant temperature, and temperature reduction.

14.6 The software control system automatically records the soldering process and the temperature control and temperature measurement curve in real time to ensure the traceability of the device process. It is automatically stored in the corresponding directory according to the process working time.

15. The V4D vacuum eutectic furnace uses a closed cavity structure to ensure long-term reliability.

When the upper cover is closed during use, it will not cause device displacement and avoid device vibration to affect welding quality. The single-chamber process meets both heating and cooling requirements.

16. V4D vacuum eutectic furnace, the upper cover is equipped with a window, and the sintering process of the device can be observed through a microscope. The upper cover is automatically raised and lowered, except for manual picking and placing, other operating software is automatically controlled.

Some customer test pictures (from customer products, please do not reprint)

Ⅱ. Accessories table

| No | Name | configuration | Quantity | |

| 1 | Vacuum eutectic furnace main body | standard | 1 set | |

| 2 | Temperature control system (TORCH) | standard | 1 set | |

| 3 | Temperature measurement system (TORCH) | standard | 2 set | |

| 4 | Vacuum system | vacuum pump (Mechanical oil pump) | standard | 1 set |

| vacuum pump (Mechanical dry pump) | Optional | 1set | ||

| vacuum pump (Japan SMC) | standard | 1 set | ||

| vacuum pump (Chengdu Ruibao) | standard | 1 set | ||

| 5 | SiC Graphite heating platform | standard | 1 set | |

| 6 | Water cooling system (including water cooling machine) | standard | 1 set | |

| 7 | Nitrogen atmosphere system | standard | 1 set | |

| 8 | Formic acid atmosphere system | standard | 1 set | |

| 9 | Nitrogen-hydrogen mixture atmosphere | Optional | 1 set | |

| 10 | Vacuum reflow control software system (Torch software control system) | standard | 1 set | |

| 11 | Industrial computer (Advantech) | standard | 1 set | |

| 12 | MFC mass flowmeter | standard | 1 set | |

| 13 | Upper heating system | standard | 1 set | |

| 14 | Positive pressure module | Optional | 2 | |

| 15 | CCD vision/microscope | Optional | 1 set | |

Remarks:

Note 1: After purchasing V4D vacuum soldering furnace, which can be put into use directly without purchasing other accessories.

Note 2: The software involved in the equipment is registered software of Beijing Torch Co., Ltd, all future upgrades will be provided free of charge to customers without third-party certification.

Note 3: In actual use, the solder and the process atmosphere nitrogen of the customer's product are involved, customer can choose to purchase according to his own process.

Note 4: When choosing solder paste process, please clean up the residual flux in the cavity and the air intake filter of the vacuum pump in time.

Note 5: The use environment of the equipment requires compressed air, nitrogen, and cooling water (the cooling-machine uses deionized water).

Ⅲ. Parameter list

| Model | V4D |

| Soldering area | 380*310mm |

| Solding height | 100mm |

| Temperature range | Max 450℃ |

| Ultimate vacuum | ≤10Pa |

| Heating rate | ≤120℃/Min |

| Cooling rate | ≤120℃/Min |

| Data interface | Serial/USB |

| Equipment control mode | Main control computer + software control system (Torch independent software) |

| Soldering process | 40 section temperature control + vacuum pressure control |

| Cooling way | Water cooling (including cool-heat-exchanger and cooling-water machine) |

| Rated power | 30kW |

| Power supply | three-phase five-wire 380V 25-50A |

| Dimension | 1200*1100*1400mm |

| Weight | 280Kg |

Ⅳ. Actual installation pictures (floor space3 ㎡)