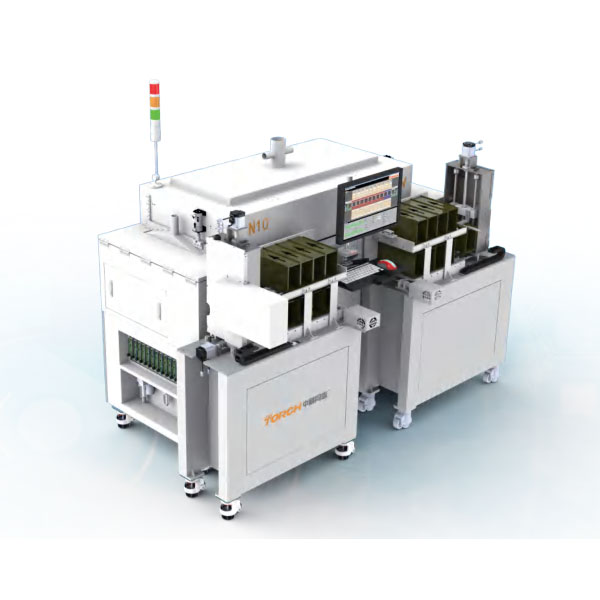

Ten Temperature Zone On-line Nitrogen Reflow Furnace - N10

* It is designed for high-quality packaging and welding of frame products and clip products.

Product Features:

The nitrogen reflow furnace is filled with nitrogen in the furnace of the reflow furnace in order to block the air inlet in the reflow furnace It prevents oxidation of the chip and frame during reflow soldering. It also prevents oxidation during preheating, welding or cooling.

The nitrogen reflow furnace is mainly used to enhance the welding quality, so that the welding occurs in an environment with little oxygen content (< 50ppm or even lower), which can avoid the oxidation problem of the chip. Therefore, the main problem of nitrogen reflow furnace is to ensure that the lower the oxygen content, the better.

According to the needs of different customers, TORCH has developed a variety of nitrogen reflow furnaces, of which the most representative is N10. N10 is a multi temperature zone on-line equipment, which is suitable for high-quality packaging and welding of frame products and clip products.

Function Introduction:

N10 is an on-line nitrogen welding furnace in 10 temperature zone to meet the capacity needs of customers.

The oxygen content is less than 50ppm, which is suitable for high-quality packaging and welding of frame products and clip products.

N10 has 10 upper and lower temperature zones, including preheating zone, high-temperature welding zone and cooling zone, At the same time, the cooling is also divided into high-temperature cooling area and low-temperature cooling area. Each temperature zone has an independent temperature control system. The current single area is controlled independently.

The equipment adopts formic acid process and nitrogen process, which can effectively remove the oxide film of weldments.

Nitrogen environment can prevent workpiece oxidation during welding. In the environment of nitrogen plus formic acid, The used solder paste does not need to contain activator, and there is no residue after welding, which is very beneficial to the welding of fine spacing devices. The combination of nitrogen, solder paste and formic acid can break the oxide, obtain the pure surface of the substrate and achieve reliable welding.

Technical Parameter:

| Model | N10 |

| Maximum heating zone length | 350×100mm |

| Number of temperature zones | 10 |

| Temperature distribution | 7 groups of heating area and 3 groups of cooling area |

| Furnace height | 15mm |

| Heating mode | Plate metal alloy heating |

| Oxygen content | <50PPM, High configuration, It can be controlled within 10ppm |

| Nitrogen consumption | 35-55L/S |

| Maximum temperature | 500℃ |

| Cooling mode | Water-cooling |

| Temp Accuracy | 1℃ |

| Rated voltage | 380V |

| Rated power | 30kW |

| Normal power consumption | 5-6kW |

| Overall dimension / weight | 1895×780×895mm/1000Kg |