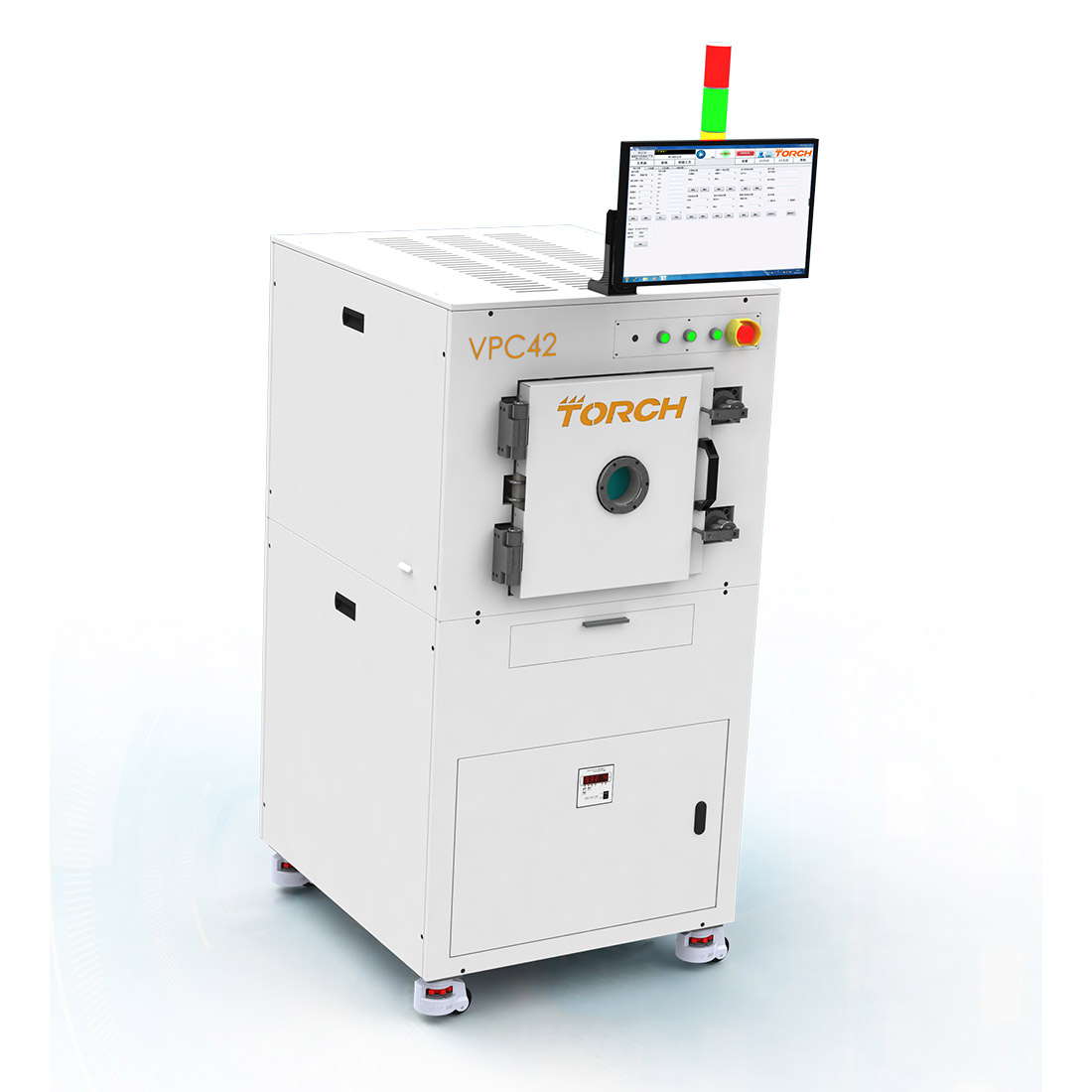

VPC42 Vacuum Plasma Cleaning Machine (Offline)

Equipment name: Offline vacuum plasma cleaning machine

Modle No.: VPC42

Manufacturer : Beijing Torch SMT Incorporated Company

I. Equipment name, type number, origin and delivery date

1. Equipment name: Vacuum plasma cleaning machine.

2. Model No.: VPC42.

3. Origin (country, manufacturer): Beijing Torch SMT Incorporated Company.

4. Delivery date: 4-8 weeks after the contract comes into effect.

5. Mainly used for plasma surface treatment process in semiconductor enclosure fields such as silicon wafer, glass substrate, ceramic substrate, IC carrier plate, copper lead frame, large-size single-sided substrate power board, IGBT module, MEMS sensor with fixture, microwave device, filter, RF device, etc.

II. Main technical performance parameters:

1. volume of vacuum chamber: 42L

2. vacuum degree:

The maximum vacuum degree of VPC42 vacuum plasma cleaner is less than 2 Pa (mechanical dry pump 40L/Minute)

3. Effective cleaning area:

Single cleaning area: 350 *350mm

15 layers: 15mm interval: 40KHZ 2KW intermediate frequency (surface treatment)

5 layers: 50mm interval, 13.56HZ 300W radio frequency (volume processing, with water cooling)

4. Height of vacuum chamber:

Chamber height: 350mm (effective size)

5. Cleaning temperature:

Low temperature cleaning (below room temperature).

6. Cleaning frequency: 30-120s

7. Cleaning effect: the dyne value can reach 70. The water drop angle is 15 degrees, and it can be optimally controlled within 10 degrees(Workshop with air cleanliness at Class 100 dust-free can be cleaned within 4 hours)

8. Gas can be used:

Argon, nitrogen, oxygen, nitrogen hydrogen mixture, hydrogen and Carbon tetrafluoride, etc.

9. VPC42 vacuum plasma cleaning machine is equipped with software control system:

The software control system is easy to operate, it enables control equipment connecting, and various cleaning process curves can be set, and curves can be set, modify, store and select for use according to different processes; The software has its own analysis function, which can analyze the process curve. The software control system will automatically record the cleaning process data, temperature curve, time and alarm related data in real time to ensure the traceability of product cleaning process.

10 The equipment does not need to be calibrated thus no more calibration fees will occur.

11 Operating power consumption:

2.5KW, excluding the power consumption of chiller(intermediate frequency)

1.5KW, excluding the power consumption of chiller (Radio frequency)

12. The function of over temperature alarm and recording. (standard configuration)

VPC42 vacuum plasma cleaning machine is functioned with workpiece surface over temperature protection,alarming, temperature safety protection and recording of the whole machine during cleaning process.

13. Nitrogen, argon and other flow management and analysis systems (Software + hardware). (Optional)

VPC42 vacuum plasma cleaning machine is functioned by real-time management and analysis of process gases such as nitrogen and argon consumed by the whole machine, and can record and analyze the gas consumption, daily consumption, weekly consumption and different time period consumption in real time.

14. Process gas pressure alarm function and analysis system (Software + hardware). (Optional)

VPC42 vacuum plasma cleaning machine is functioned by undervoltage alarm, recording and analysis of process gas source in the production process of the whole machine, which is very useful for product quality traceability.

15. Energy management and analysis system (Software + hardware). (Optional)

VPC42 vacuum plasma cleaning machine is functioned by real-time management and analysis of energy consumption, and can analyze the recording of real-time power consumption, daily power consumption, weekly power consumption, time period power consumption, etc.

16. With output statistical management and analysis system (software + hardware). (Optional)

16. With output statistical management and analysis system (software + hardware). (Optional)

The VPC42 vacuum plasma cleaning machine has the function of real-time management and analysis of the output of the vacuum processing products of the whole machine. It can log and record and analyze the real-time shift output, daily output, weekly output, and monthly output for product quality traceability and analysis.

17. MES data interface subsystem (Software + hardware). (optional)

VPC42 vacuum plasma cleaning machine is also functioned by MES data interface of the whole machine, and MES system can be selected and configured to complete various data acquisition and analysis of intelligent equipment.

18. Overall dimensions:

850*960*1680mm (excluding alarm light)

19. Internal structure: see the right figure

III. Basic composition and configuration:

| No | Description | configuration | qty |

| 1 | vacuum plasma cleaning machine | Main machine | 1 set |

| 2 | Plasma power system | Standard configuration | 1 set |

| 3 | Temperature measurement system | Standard configuration (2 groups of temperature measuring thermocouple, 1 for use, 1 for backup) | 1 set |

| 4 | Vacuum system | Standard configuration | 1 set |

| 5 | Mechanical pump | Standard configuration | 1 set |

| 6 | Water cooling system | Standard configuration (Industrial cooling machine is excluded) | 1 set |

| 7 | Industrial cooling machine | Optional | 1 set |

| 8 | Process gas system | Standard configuration (Process gas pipeline and interface) | 1 set |

| 9 | Nitrogen atmosphere protection system | Standard configuration (exclude nitrogen souce supplying) | 1 set |

| 10 | vacuum plasma cleaning machine software system | Standard configuration (control software) | 1 set |

| 11 | Industrial computer | Standard configuration | 1 set |

| 12 | Plasma | Standard configuration | 1 piece |

| 13 | Temperature measurement sensor (spare parts) | Standard configuration | 2 |

| 14 | Cooling pipeline (spare parts) | Standard configuration | 2 |

| 15 | Process gas volume management and analysis system | Optional | 1 set |

| 16 | Process gas pressure alarm and analysis system | Optional | 1 set |

| 17 | Power management and analysis system | Optional | 1 set |

| 18 | Oxygen content management and analysis system | Optional | 1 set |

| 19 | MES data interface system | Optional |

IV. VPC42 Technical parameter

| Brand | Manufacturer | Beijing Torch SMT Incorporated Company | Remarks |

| Brief introduction | Origin | Beijing | |

| Key components | Temperature sensor | US OMEGA | |

| Vacuum pump | KYKY/BSC | ||

| Globe valve | Japan brand | ||

| Corossion resistence valve | Japan brand | ||

| Low voltage electric system | SCHNEIDER | ||

| Botton switch | Taiwan JICTEN/SCHNEIDER | ||

| Magnetic proximity sensor | Omron | ||

| Heater | TORCH | ||

| Key technical index | Temperature | Low temperature cleaning, temperature is maintained under room temperature | |

| Min. Vacuum degree | 5pa | ||

| Oxygen content | <1ppm | ||

| Production efficiency | 20-120S | ||

| Key process index | Quality traceability | 1. Process gas pressure alarm record. 2. Oxygen content alarm record. 3. Temperature over temperature alarm record. 4. Alarm record of non-compliance of vacuum value |

|

| Intelligence and informatization | 1. Intelligent function. If one of the above 4 indicators fails to meet the standard or gives an alarm, an overall alarm and prompt to stop production will be displayed to ensure the production quality. 2. Energy management system, power consumption and nitrogen consumption are counted and displayed in real time in the energy management system. 3. All above information can be seamlessly connected to MES system through data interface to facilitate the decision-making and management of management team. |

||

| Facilities | Power | 380VAC, 20A | |

| Gas | Compressed air (CDA) 0.5Mpa | ||

| Nitrogen | 0.5Mpa | ||

| Vacuum | Equipped with vacuum dry pump |

Note:

The control software for the vacuum plasma cleaning machine of Beijing Torch SMT Incorporated Company is independently developed by Beijing Torch SMT Incorporated Company and Beijing Torch SMT Incorporated Company pocesses the right of software registration without third-party certification.

The vacuum plasma cleaning machine from Beijing Torch SMT Incorporated Company has already obtained a number of national patents. Please do not risk copying!!