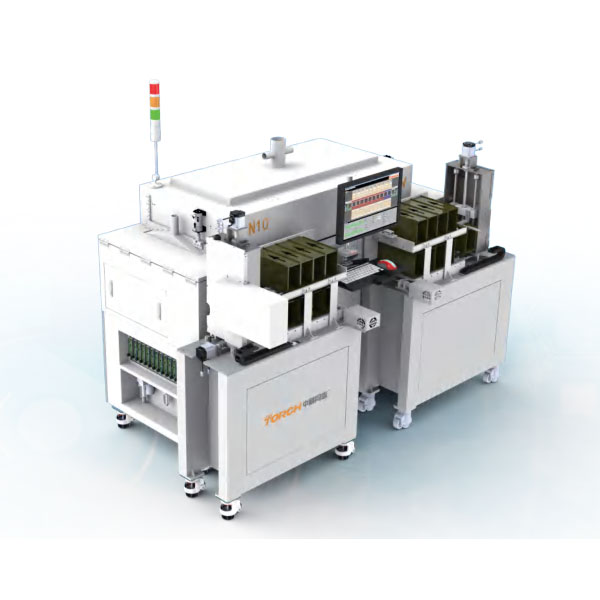

VDO300 Vacuum Exhaust Furnace

Equipment Description:

VDO300 vacuum exhaust furnace is a new type of vacuum exhaust equipment newly launched by quartz bearing platform technology.

It is used for exhaust and degassing of semiconductor chip, frame, support, solder chip and other products.

Technical performance introduction

1) Exhaust temperature:

The actual maximum exhaust temperature of VDO300 vacuum exhaust furnace is ≤ 300 ℃.

2) Vacuum degree:

Equipped with mechanical oil pump (high-speed rotary vane vacuum pump 40L / M), the maximum vacuum degree is within 30 PA.

3) Effective exhaust area:

VDO300 exhaust area: 600 * 220mm / layer * 3 layers, layer spacing: 100mm.

4) Heating method:

Quartz glass platform + infrared heating.

5) Heating rate:

Quartz bearing table: the maximum heating rate is 40K / min.

6) Cooling function:

Vacuum natural cooling.

7) Temperature control accuracy:

VDO300 vacuum exhaust furnace adopts the temperature control technology of Comrade Zhongke, and the temperature control accuracy is ± 2 ℃.

8) The cavity is provided with an observation window for observing the exhaust process of devices inside the cavity.

9) VDO300 vacuum exhaust furnace machine is equipped with software control system:

Various exhaust process curves can be set freely.

The exhaust temperature curve can set up to 40 temperature segments to meet the accurate temperature control in the heating process.

The exhaust process can be set by itself according to requirements, and unlimited process setting.

The software control system of VDO300 realizes the functions of setting, modifying, storing and calling exhaust process curve for use.

The process curve during gas is recorded in real time and automatically saved to ensure the traceability of exhaust process. Software built-in analysis Function, which can analyze the process curve and determine the temperature rise, constant temperature, temperature drop and other information.

II Accessories list:

| No | Description | configuration | QTY |

| 1 | vacuum exhaust furnace | standard | 1 set |

| 2 | The temperature control system | standard | 1 group/floor |

| 3 | The temperature measurement system | standard | 1 set |

| 4 | One set vacuum system | standard | 1 set |

| 5 | One mechanical oil pump | standard | 1 set |

| 6 | Water cooling system | standard | 1 set |

| 7 | Industrial chiller | standard | 1 set |

| 8 | quartz wafer support table | standard | 1 set |

| 9 | industrial computer | standard | 1 set |

| 10 | One industrial computer | standard | 1 set |

| 11 | tool | standard | 1 set |

Note 1: VDO300 vacuum exhaust furnace purchased by customers can be directly put into use without purchasing other accessories.

Note 2: the software involved in the equipment is the registered software of TORCH, future upgrading involved are provided to customers free of charge without third-party certification.

III Parameter

| Model | VDO300 |

| Exhaust area | 600mm * 220mm * 3 layers |

| Exhaust height | 100mm (layer spacing) |

| Temperature range | up to 300 ℃ |

| Limit vacuum | ≤ 10Pa (equipped with 40L / M mechanical oil pump) |

| Heating rate | ≤ 40K / min |

| Data interface | serial port / USB port |

| Equipment control mode | industrial computer + software control system (comrades' independent software) |

| exhaust process | Temperature control + vacuum pressure control in section 40 of exhaust process |

| Cooling mode | water cooling |

| Rated power | 26kW normal power 12kW |

| Power supply | three item five wire 380V 25-50a |

| Overall dimension | 1350 * 1000 * 1830mm |

| Weight | 800kg |