Quantity

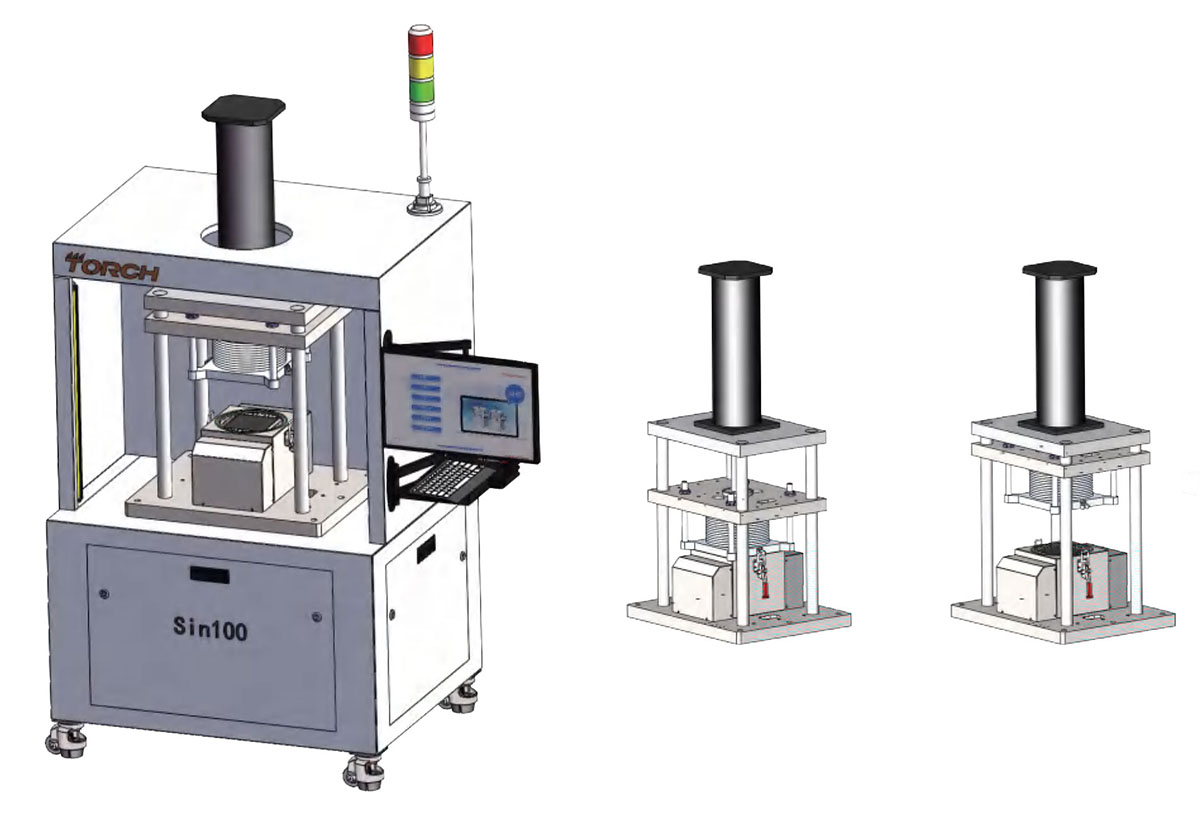

Nano Silver / Nano Copper Positive Pressure Sintering Furnace SIN100

Function Introduction:

Nano silver / nano copper positive pressure sintering furnace mainly focuses on mechanical pressure curing. In the selection of pressure equipment, this design uses precision hydraulic control system to achieve high-precision pressure.

Vacuum sealing structure design is adopted in the overall furnace cavity and structure design. During curing, it can be cured in vacuum environment or other inert gas (two or more) protective atmosphere to improve the curing quality of products.

The overall equipment includes: pressure system, vacuum system, heating system, temperature control system, cooling system, etc.

Technical Parameter:

| Type | SIN100 | |||

| Curing area | 100*100mm | |||

| Furnace height | 5-100MM (other heights are optional) | |||

| Mechanical pressure | 55MPa | |||

| Limit vacuum | ≤3Pa,working vacuum10-200Pa | |||

| Heating mode | metal armored heater, cemented carbide carrier | |||

| Temperature uniformity | within effective curing area ≤± 1% | |||

| Max heating speed | 120-240℃/min | Max cooling speed | 60-120℃/min | |

| Curing void rate | less than2% | |||

| Control mode | 40 section temperature control + vacuum pressure control | |||

| Temperature curve | Can store several 40 segment temperature curves | |||

| Cooling mode | water cooling + air cooling | |||

| Feeding mode | manual feeding | |||

| Pre tightening / mechanical pressure | quick locking device/50MPa | |||

| Voltage | 220V 25-50A | dimension | 1000×800×2050(mm) | |