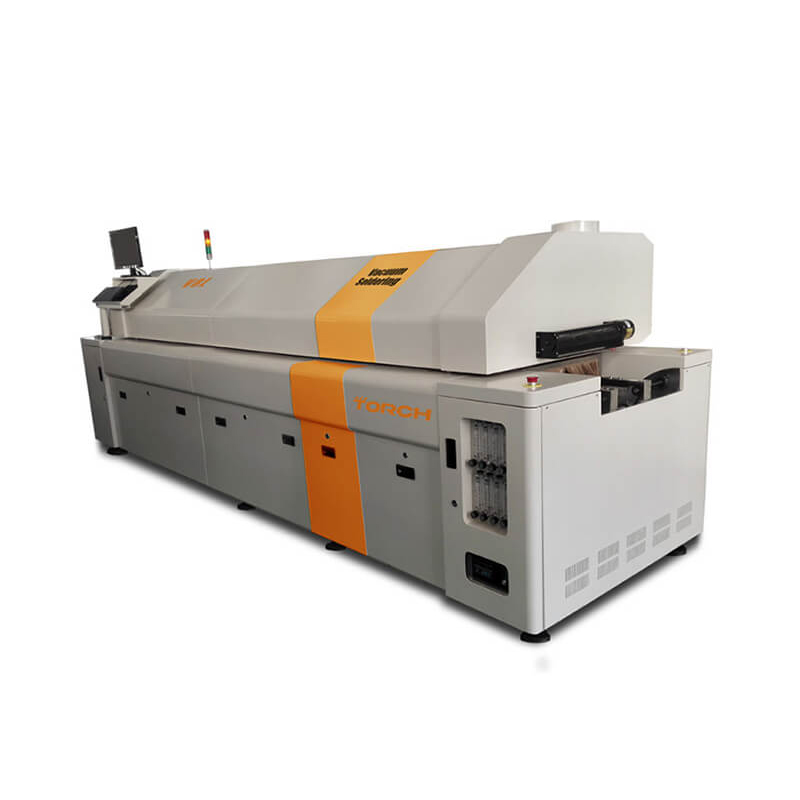

Online Vacuum Reflow Oven VRO945

-Optimized design for bridge stacks, frame products and CLIP products

Features:

1. VRO945 on-line vacuum reflow furnace has the characteristics of large output, low energy consumption, and low nitrogen consumption.

2. VRO945 is specially designed and optimized for the special needs of vacuum welding packaging of lead frame products in the semiconductor industry and vacuum welding packaging of CLIP products. Taking into account the many problems encountered by customers in the industry, a vacuum furnace has been carefully optimized and designed.

1). Low oxygen content: The oxygen content is less than 20ppm.

2). Low energy consumption: Machine start power: 18KW; Machine average working power: 7KW

3). Low nitrogen consumption: Nitrogen consumption is only 1/3 of other similar vacuum furnaces.

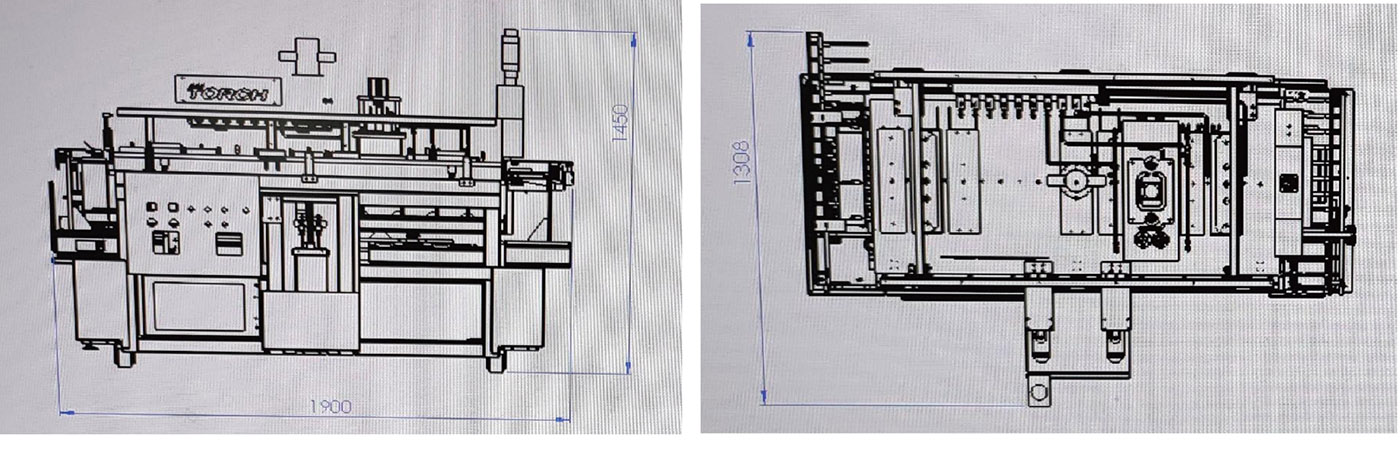

4). Small space: Dimensions: 1900*1308*1450mm

Function introduction:

1. Meet a variety of solder (≤ 450 ℃) welding requirements:

For example: SAC305; Sn63Pb37; Sn90Sb10; In97Ag3; In52Sn48 etc.

2. Soldering Void rate: Pad Void rate: <1%. Single Void rate: 2%. Different welding materials and air atmosphere will have an impact welding. The current data is based on customers’ comprehensive testing data. The data will be a little different when involved in different welding products.

3. Supports nitrogen atmosphere working environment, meeting a variety of welding processes.

4. Vacuum reflow oven is equipped with software control system, modular setting and operation interface.

5. The equipment doesn’t need to be corrected, and there will be no extra calibration charges.

Equipment configuration

| No. | Configuration | Qty |

| Temperature control system | Standard | 1 set |

| Temperature test system | Standard(4sets temperature thermocouples) | 2 sets |

| Vacuum system | Standard | 1 set |

| Industrial computer | Industrial PC | 1 set |

| Heating platform | Alloy heating platform | 2 sets |

| Water-cooling system | Standard(water-cooling machine,water-cooling pipes and connectors) | 1 set |

| Nitrogen atmosphere protection system | Standard(Nitrogen pipes and connectors) | 1 set |

| soldering flux recycling system | Optional (soldering flux cooling & filtering system and connectors) | 1 set |

| Vacuum reflow oven control system | Standard(Control software) | 1 set |

Technical Parameter

| Online Vacuum Reflow Oven VRO945 | |

| Welding area | 320mm×100mm |

| Furnace cavity height | 16mm(25mm optional) |

| Working height | 900±50mm |

| Transmission mode | Step-by-step steel belt transmission |

| Number of temperature zones | 9 temperature zone |

| Maximum temperature | 450℃ |

| Heating mode | Plate heater |

| Cooling method | Water-Cooled |

| Flux recovery device | Optional |

| Oxygen content | ≤20ppm |

| Minimum vacuum value | 50pa |

| Vacuum pumping rate | Greater than 6 L / S |