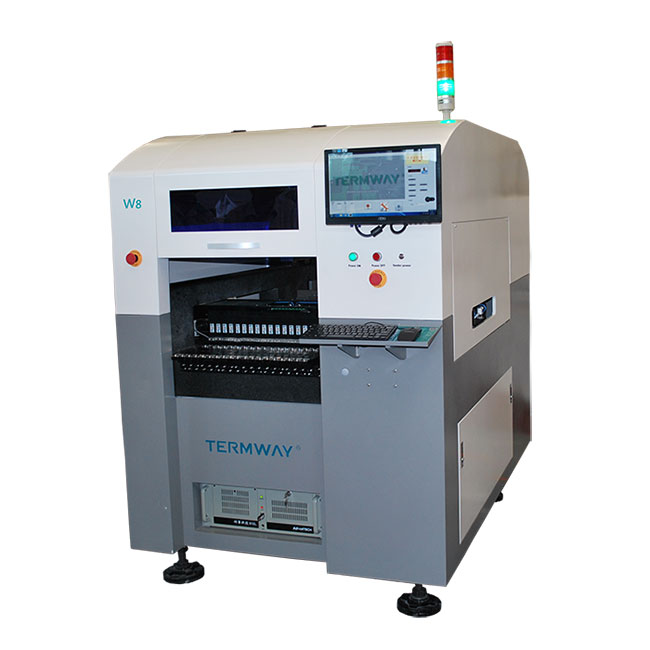

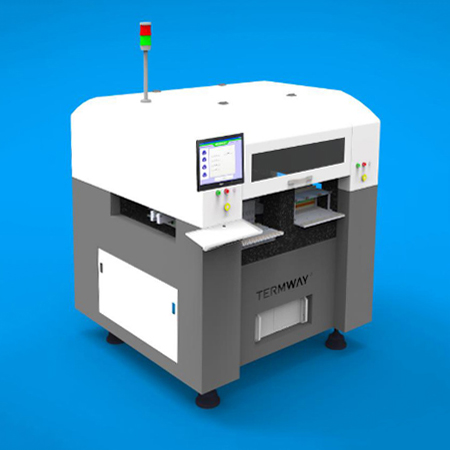

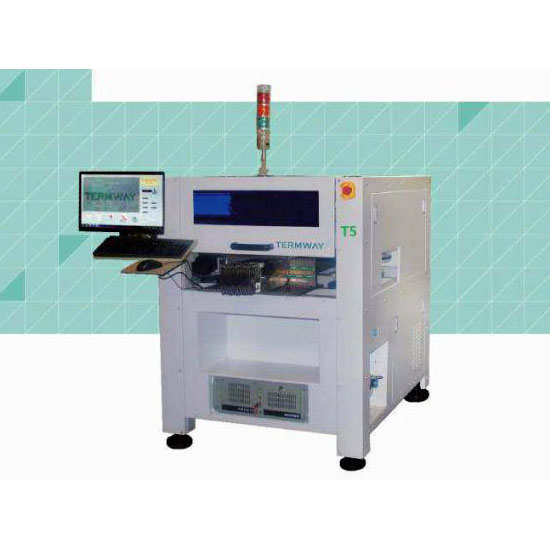

Pick and Place Machine for Wafers Model: W6/W8

- Introduction:

W6 / W8 unique:

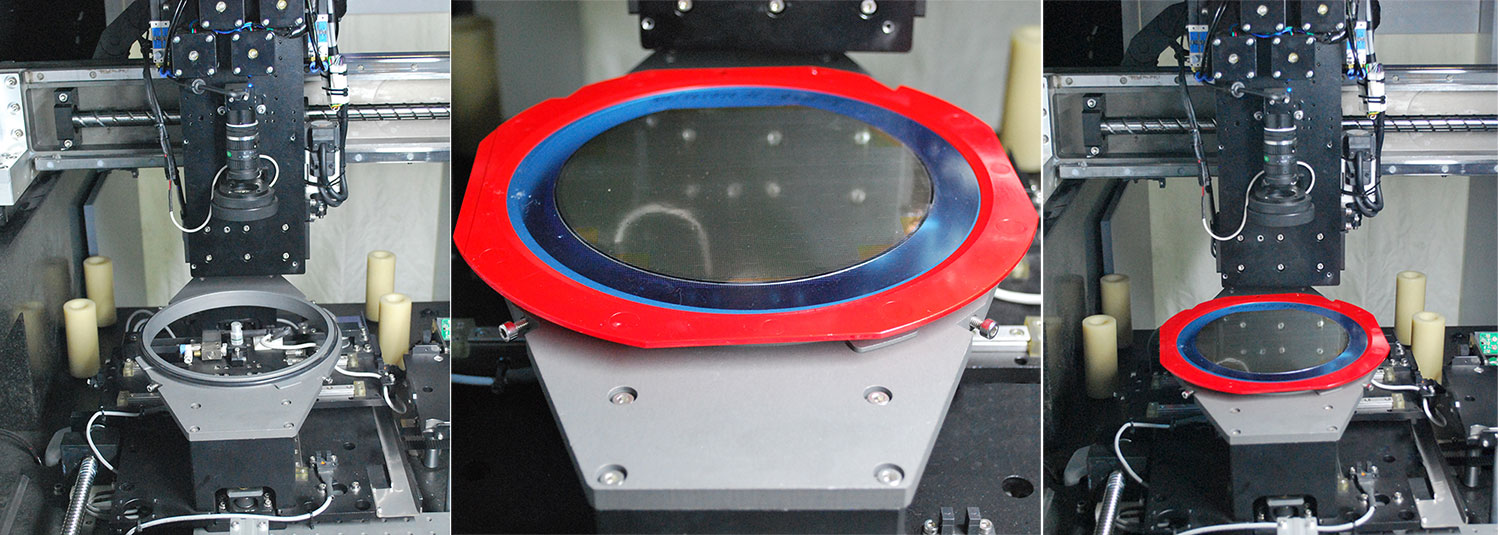

1. On a standard placement machine platform, Realized the chip feed by the wafer feeder to complete die-mount capabilities.

2. It can mount 4 inches, 6 inches, 8-inch wafer.

3. Configuring world-class linear encoder to make sure the whole machine high precision motion control and high-precision repeat placement.

4. It supports a variety of feeding methods to meet the needs of mixed-mount.

W6/W8 General features:

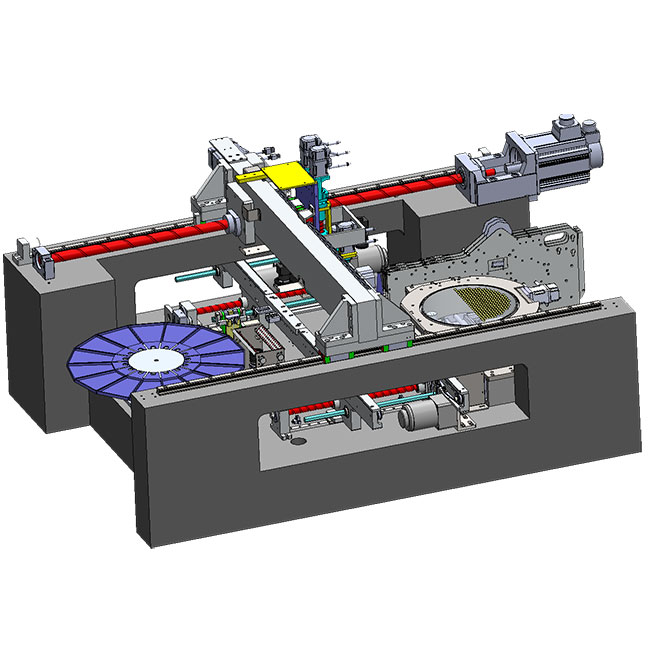

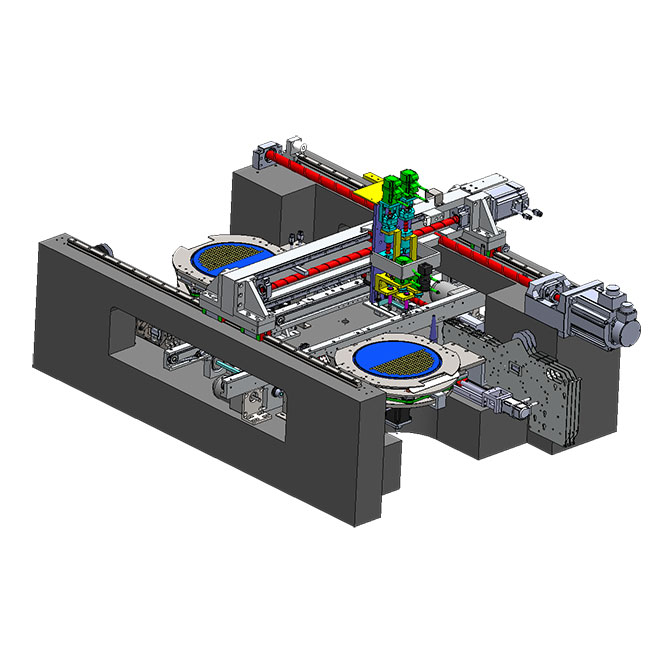

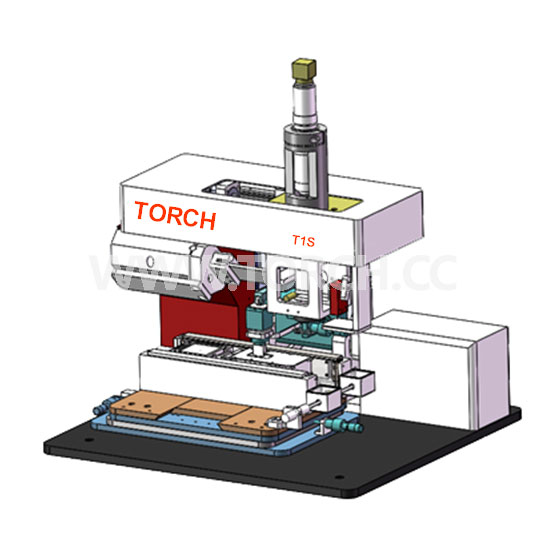

1. Mount base platform for high-precision placement machine T8S, inherites advantages of the apparatus to meet the high-speed, stable and accurate placement. (Reference: the current T8, marble platform, linear motor part, non-stop scanning part, a transmission system).

2. Realizing chip feeding by water feeder in order to complete bare chip's placement.

3. On the basis of the wafer feeder, can also configure a variety of feeder system, such as: electric feeder, electric smart feeder, vibrating feeder, IC plate, vibration plate, and customized feeder, etc. (the appended drawings: GF feeder, vibration feeder, IC, etc.

4. It can mount 4 inches, 6 inches, 8-inch wafer).

5. Differentiation of the suction nozzle tailored to meet the specific requirements of the chip, avoid damage to the chip.

6. Equipped with off-line programming software to achieve new products fast import.

Optional parts:

1. GF Feeders (8MM, 12MM, 16MM, 24MM, 32MM, 44MM).

2. Nozzles (6 kinds Nozzles, you can customize different nozzles).

3. QS48 component (can mount 48*48MM IC).

4. bulk trays (Different size of compoents).

5. IC tray.

6. Stick feeders.

7. Off-line programming software

| W6 | W8 | ||

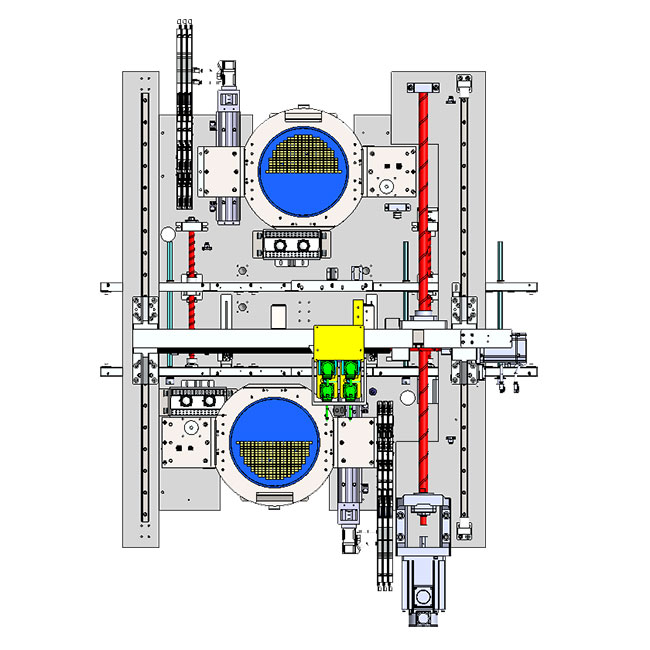

| 1 | Mounter head | 4 heads | 4 heads |

| 2 | Mounter area | 50mm×50mm~350mm×250mm | 50mm×50mm~350mm×250mm |

| 3 | Z Axiz max move range | 30mm | 30mm |

| 4 | Typical Max Speed | 800CPH | 800CPH |

| 5 | Theoretical Max Mount Speed | 4000cph--6000cph | 4000cph--6000cph |

| 6 | Moving System | XY axis servo motor driver +Ground ball screw +linear encoder (X axis can select moving coil ) | XY axis servo motor driver +Ground ball screw +linear encoder (X axis can select moving coil ) |

| 7 | XY Axis Precision | ±0.001mm | ±0.001mm |

| 8 | Repeat mount precision | ±0.01mm | ±0.01mm |

| 9 | Position manner | Visional position | Visional position |

| 10 | Component available | Minimum 0.3*0.3*0.15mm—38*38mm*8.5 | Minimum 0.3*0.3*0.15mm—38*38mm*8.5 |

| 11 | Programm method | Automatic data input/ Video learning / Keyboard input | Automatic data input/ Video learning / Keyboard input |

| 12 | Feeder Qty | 36 kinds of 8mm feeders | 36 kinds of 8mm feeders |

| 13 | Wafers Qty | 1 | 1 |

| 14 | Wafers Size | 6 inch | 8 inch (also 6 inch ) |

| 15 | Operation system | WINDOWS XP/WIN7 32bit | WINDOWS XP/WIN7 32bit |

| 16 | Compressed air | 80psi (0.5Mpa, gas flow ≥160L/M) | 80psi (0.5Mpa, gas flow ≥160L/M) |

| 17 | Power | 380v, 50Hz, 5kw | 380v, 50Hz, 5kw |

| 18 | Weight | 950kg | 980kg |

| 19 | Dimension | 1700 (L)×1200(W)×1440(H) | 1700 (L)×1200(W)×1440(H) |