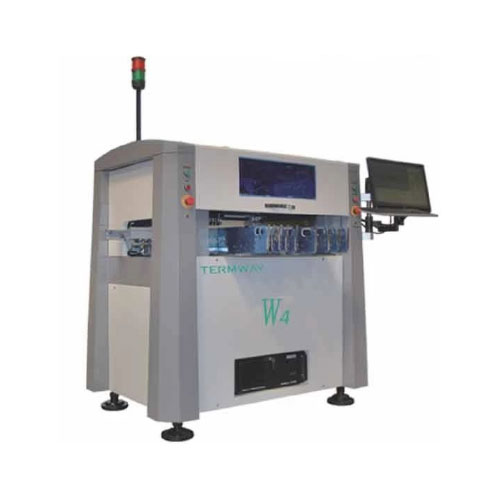

Hybrid Wafer Mounter W4

- Introduction:

1. It is suitable for the mounting of multi chip, solder chip, resistor capacitor and other hybrid parts.

2. The smallest RC components and solder tabs with a size of 0.6*0.3mm can be mounted.

3. Max Mount110*100mm modules and soldering pads.

4. Equipped with the world's first-class grating ruler to realize the high-precision motion control and high-precision repeated mounting.

4. The mounting pressure is controllable.

5.The patented granite movement platform ensures the accuracy of the equipment for more than ten years.

Features:

1. The whole machine adopts modular structure. The bottom platform and x-axis and y-axis gantry structures are all granite platforms. It can effectively ensure the reliability and stability of the placement machine in long-term use.

2. The whole machine adopts first-class high-precision guide rail to effectively improve the placement accuracy.

3. The whole machine adopts high-definition imported industrial camera to complete the visual alignment and mounting of high-precision chip and special-shaped electrode.

4. It can automatically identify mark points and effectively improve the production efficiency and precision of the placement machine.

5. Automatic visual programming without manual input of component coordinates. Programming is simple and convenient for beginners. At the same time, it can import map data to facilitate the production mode of small batch and multi variety products.

6. Two sets of small trays are standard.

7. The whole machine is equipped with 8 suction nozzles in standard.

8. Cost effective automatic placement machine, most suitable for IGBT, rectifier, thyristor, fast recovery, SCR, led and other products.

9. The whole machine is equipped with a set of transmission system. It can connect screen printing machine, connecting table and vacuum reflow welder seamlessly.

10. Equipped with automatic nozzle changing system, 22 different nozzles can be changed freely.

11. The whole machine has automatic detection function of circuit board height and alarm function of component picking failure, which can effectively improve the production quality.

The whole machine has the function of material shortage alarm, which can be unattended in mass production.

12. The whole machine has the function of material shortage alarm, which can be unattended in mass production.

Technical Parameter:

| Model | W4 | ||

| Mounting accuracy | X/Y axis ±15µm@3σ | Angle | ±0.9° |

| Mounter head | 3 groups mount /1 group solder paste | XY axis resolution | ±0.001mm |

| Belt feeder | Can optional place 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm feeders and special feeder for solder pad | ||

| Number of feeders | Can place 70 pieces of 8mmGF feeders | ||

| Wafer feed | Waffle tray | ||

| Moving system | XY servo motor driver + Industrial double synchronous drive + grating scale positioning | ||

| Component available | Above 0201 RC-component and 110*100 modules and pads | ||

| Programming mode | Automatic data import / Vedio learning / Keyboard input | ||

| Solder pad | Standard | Solder Paste | Standard |

| Mounting pressure | 30-300 Controlled | Max move range | 580*505mm |

| Typical chip speed | 4000-5000uph | Z axis max move range | 20mm |

| Repeat placement accuracy | ±0.015mm | Position method | Visual position |

| Operating system | WINDOWS XP | Compressed air | 800psi(0.5Mps), Gas flow 80L/M |

| Fixture loading and unloading | Automatic online completion | Weight | 70kg |

| Industry 4.0 | Predictive maintenance, consumables safety life reminder, barcode identification, Mess data interface, Map tracking | ||

| Power | 220v, 50Hz, 4kw | ||

| Dimension | 1400(L)*1200(W)*1450(H) Not contain Alarm light | ||