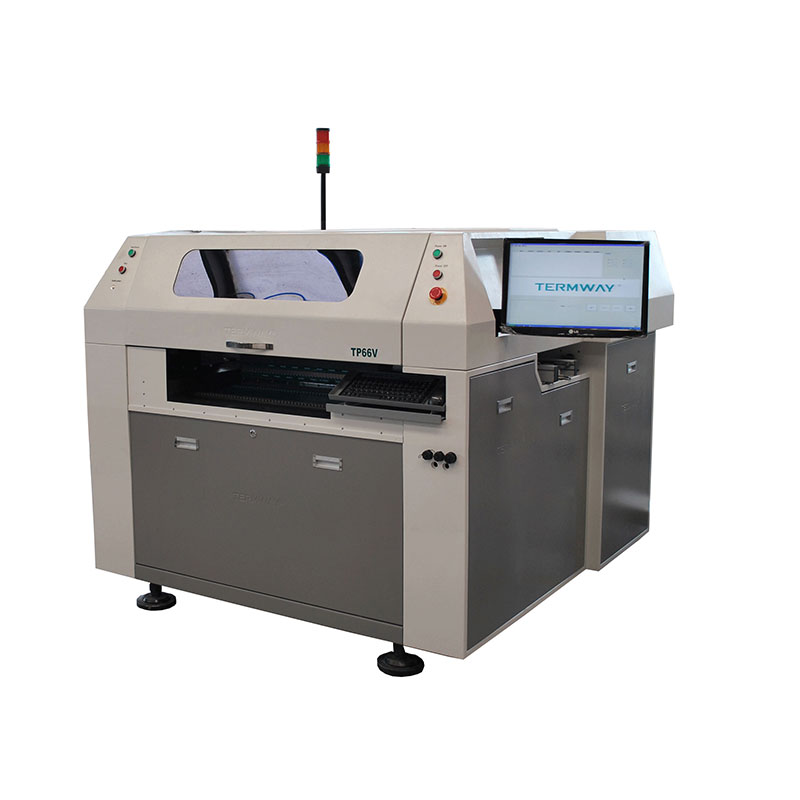

Automatic Pick and Place Machine TP220

- Product Description

Automatic pick and place machine TP220 is the most cost-performance equipment in the market, it mounts variety of components by vacuum nozzle. The machine can mount SMD components 0603 and above, SOIC ect; it can equip GF feeder, Z axis can rotate, which can meet various angle of SMD component.

- Technical Data Sheet

TP220 Summary:

1. Component available for below 20mm SOP columnar diode, triode, SOT, SOP, IC chips and and 0603 component (except of 5m Aluminum electrolysis electric capacitor) ect

2. Intelligent electrical feeder

3. Program and mounting technology for multi –panels

4. Off-line program function

5. Program control

6. Visional program

7. Powerful data import function, any formats of PCB file can be imported. a new program can be finished in 10 minutes

8. Stably pick and place SMD 0402

9. Security cover for protection of operator to dustproof

10. High precision linear guiderail

11. Configurate 5 kinds of nozzle, software reminds of "nozzle changing"

Product introduction:

Automatic pick and place machine TP220 is the most cost-performance equipment in the market, it mounts variety of components by vacuum nozzle. The machine can mount SMD components 0603 and above, SOIC ect; it can equip GF feeder, Z axis can rotate, which can meet various angle of SMD component.

Features:

1 With exact quadrate guide rail, it can improve picking accuracy.

2. It use visional programme system, which can help component programme position.

3. Can import board CAD data as mouting data to realize automatic programme, which is no need to imput coordinate. Programme is simple for easy to learn for fresh man.

5. Nozzle can be changed by manual according to different size of component.

6. High cost-performance automatic mounter, it is suitable for small quantity of mass production, R&D and personal use, especially mini-type electronic mass production

7. Industrial computer cooperate with professional software control to use, which is convenient for operation.

8. Very stable and convenient for programme and mounting of panel boards.

9. In software will shows that all coordinates of panel boards, and micro-adjust for these coordinate to realize high precision mounting.

10. It can set space of each panel board in software, and display all feeding coordinates according to the space, can take out of panel boards that need not to mount.

11. If board manufacture has quality problem, it can deviate and improve all feeding place.

12. Software can help double heads to realize automatic optimization function.

13. It adds limit inspection function in software when XYZ axis moves.

14. It adds 6 gear speed control function in software, you can get the perfect speed according to distance check sheet and speed setting, which can improve mounter’s stability for a long term.

Configuration:

Industrial computer 1 suit

Mounting head 2 group

Nozzle 2 pcs

Optional:

1. 8mm, 12mm, 16mm and 24mm automatic feeder

2. Nozzle

3. Industrial Pump

4. UPS Uninterruptible power supply

Technical Parameter:

| TP220(two heads) | |

| max PCB size | 300×200mm |

| max moving range | 380×350mm |

| max moving range of Z axis | 10mm |

| Typical picking speed | Max speed: 4000CPH actual speed: 2600-3500PH |

| Resolution | ±0.015mm |

| Repeat accuracy | ±0.15mm |

| Position method | Machinery position |

| Components can mount | 0603 and above SMD component and SOIC (below 15mm) |

| Programme method | Video programme /software program input |

| Riving method | Industrial synchronous belt drive |

| Belt feeder | 8mm, 12mm GF type electric intelligent feeder (optional) |

| Feeder number | 23 pcs of 8MM GFTA-08S electric feeder can be set in front |

| Compressed air | 80psi(0.5Mpa) |

| Power supply | 220V, 50Hz |

| Weight | 126kg |

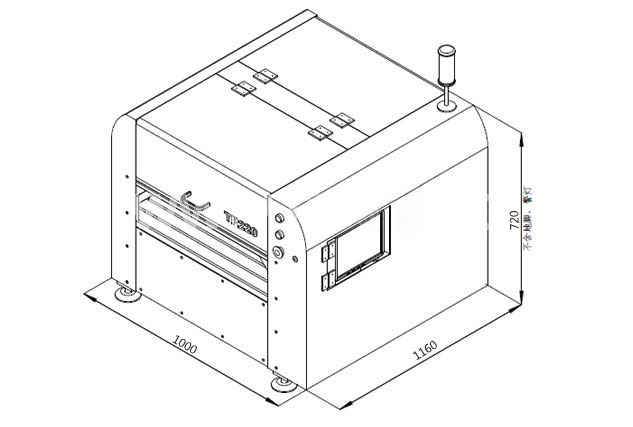

| Dimension | 1000×1160×720mm |