Automatic Visional Pick N Place Machine TP210+

- Product Description

Automatic pick and place machine TP 210+ is a mini-type desk high speed pick n place machine. It is a cost and effective machine. TP210+ can mount 0603, 0805, 1206 etc and SOP, SOIC (size under 15*15mm, PIN foot less than 24) TP210+ equips 22 pcs of 8 feeders (electric feeder 8mm, 12mm, 16mm, 24mm can choose), Z axis can route freely. It can meet mounting require of various of angle component.

- Technical Data Sheet

TP210+ Summary:

1. Component available for below 20mm SOP columnar diode, triode, SOT, SOP, IC chips and and 0603 component (except of 5m Aluminum electrolysis electric capacitor) ect.

2. Intelligent electrical feeder.

3. Program and mounting technology for multi–panels.

4. Off-line program function.

5. Program control.

6. Visional program.

7. Powerful data import function, any formats of PCB file can be imported. a new program can be finished in 10 minutes.

8. Stably pick and place SMD 0402.

9. Security cover for protection of operator to dustproof.

10. High precision linear guiderail.

11. Configurate 5 kinds of nozzle, software reminds of "nozzle changing".

Introduction:

Automatic pick and place machine TP 210+ is a mini-type desk high speed pick n place machine. It is a cost and effective machine.

TP210+ can mount 0603, 0805,1206 etc and SOP, SOIC (size under 15*15mm, PIN foot less than 24)

TP210+ equips 22 pcs of 8 feeders (electric feeder 8mm, 12mm, 16mm, 24mm can choose), Z axis can route freely. It can meet mounting require of various of angle component.

Main parts:

Step motor with an angle change function.

TP210+ can mount 45°, 90°,180° angle component.

Dual Parallel square-type wide guiderail.

Compared with balling guiderail, the guiderail has a small space to ensure precision accuracy.

Visional+ machinery position system.

Camera nearby mounting head can magnifying ' + ' cursor to make Mark point position more accurate.

No-contact flying centering system.

Flying centering system can mount most of SMD components include: 0603, 0805, 1206 etc and SOP, SOIC (size under 15*15mm, PIN foot less than 24)

Flexible reference point system(RPS):

In addition to standard Round reference point, square PCB pad and ring PCB pad with hole also can be identified as a reference point.

All-purpose automatic feeder

50 pcs at most of automatic feeder, 8mm, 12mm,16mm, 24mm, you can choose to install according to your component type and your required speed.

It uses unique Air suspended pick-and - place head design which can transmission several kinds of large and small component.

Protel file of component data import.

Software control, limitless data file can save in PC, you can call them at any time when you need, easy to operate.

Technical Parameter:

| Type | TP210+ |

| Max PCB size | 300x200mm |

| max moving range | 400×460mm |

| max moving range of Z axes | 10mm |

| Typical pick&place speed | 2600-3000cph |

| max pick&place accuracy | ±0.014mm |

| repeat accuracy | ±0.05mm |

| Positioning | Visional Position+ Machinery Position |

| Component Available | 0603, 0805, 1206 etc and SOP, SOIC (size under 15*15mm, PIN foot less than 24) |

| Program way | Software program input |

| Driving mode | use industrial Synchronous belt to drive |

| Automatic Feeder | 8mm, 12mm, 16mm, 24mm feeder can choose |

| Feeder Num | Can set 50 pcs of 8mm feeder |

| IC Plate Num | More than 1 |

| Operating system | WINDOWS XP |

| compressed air | 80psi (0.5Mpa) |

| Power supply | 220V, 50Hz |

| Weight | 95kg |

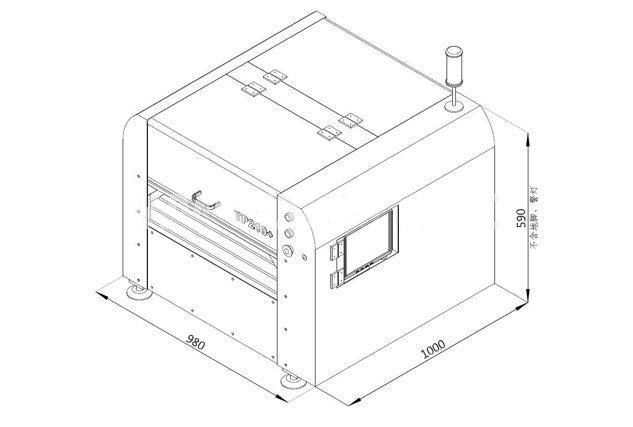

| Dimension | 980×1000×590mm |