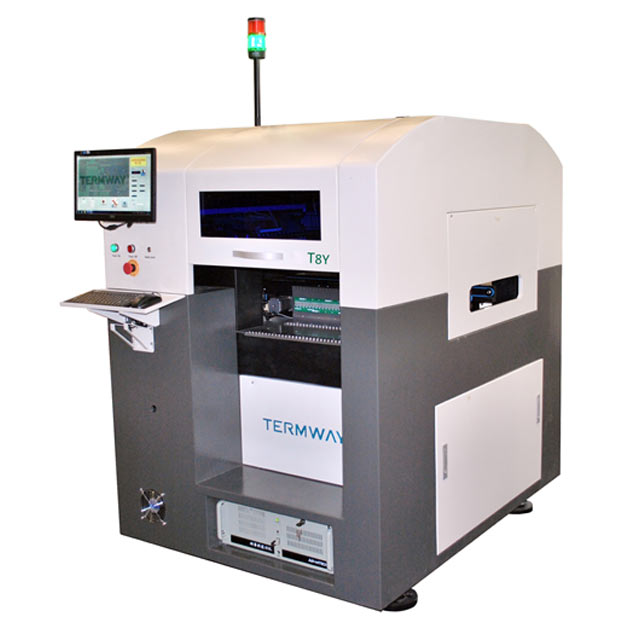

Automatic Mounter TP320V

- Product Description

TP series is a fully automatic desktop SMT placement machine, it can be mounted various of component through a vacuum nozzle, it is currently on the market cost-effective automatic placement equipment. The machine is suitable for most of the SMD chip components 0603, SOIC, PLCC and QFP IC; visional system meets high precision of 0.65mm pitch BGA or QFP IC chips such as the placement, in additional to the standard round reference point, no screen printing solder paste and square PCB and ring type through-hole pad also can be as a reference point.

- Technical Data Sheet

TP320V Summary

1. Automatic mounter with precision spare parts.

2. High precision machine after annealing treatment, high frequency oscillation and natural aging.

3. Scraping movement planer makes the accuracy reach 0.01mm.

4. Precision level P guide rail (repeatability of 0.02mm and good abrasion resistance).

5. Patented mount model.

6. Electric intelligent feeder.

7. Chemical cromalin hardening process on PCB seat and feeder seat. (SMC spare part)

8. The only one desktop mounter that can place 50 types of component.

9. Patented out-look design.

10. Powerful data import function, any formats of PCB file can be imported. a new program can be finished in 10 minutes.

11. Software control system for placement, can match famous brand Siemens.

12. The desktop visional mounter with off- line program function.

13. The one can realizes remotely maintain and analysis and inspection function.

14. The one and only automatic desktop visional mounter for 0402 and 0.5mm QFP.

15. Equips good quality industrial control computer.

16. Equips Tunable optical generator to satisfy different colors for the identification of component.

17. Silence, noise never go up to 50 db.

18. Actual speed: 5000cph.

19. Software reminds of maintainance period.

20. LOGO is Stamp-formed.

Features:

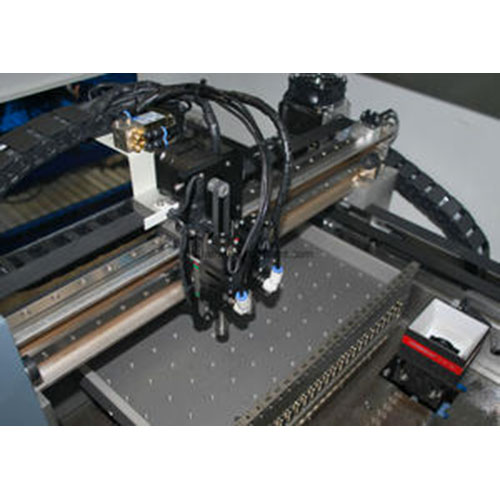

1. Cast structure, the bottom platform and Y-axis gantry structure uses casting process in SMT line, which effectively guarantee a reliability and stability for long-term use.

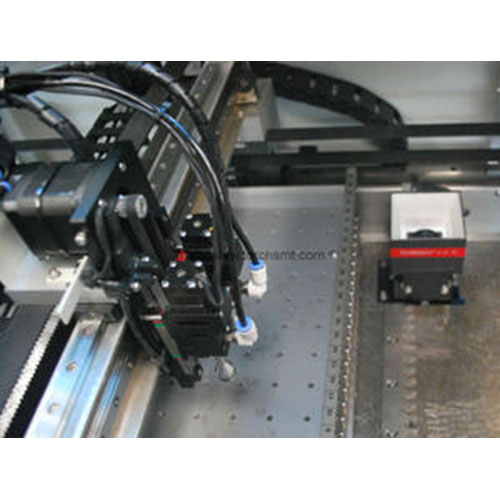

2. It uses high precision guides to improve placement accuracy.

3. High-resolution industrial camera to complete the visual position mount of high-precision components.

4. Vision system can automatically identify MARK point to improve production efficiency and chip placement accuracy.

5. Automatically visual programming without input device coordinates by hand. Programming is simple, easy for beginners to learn.

6. A small IC tray as standard configuration.

7. 5 nozzle as standard configuration, the software will remind you to replace the nozzle.

8. Cost-effective automatic placement machine, it is most suitable for small scale production, research and personal use.

Optional:

1. GF electric feeder (CF type as alternative models suitable for low-cost production and R&D use).

2. Nozzle.

Technical Parameter

| Model | TP320V |

| PCB board size | 350×210mm |

| Max moving range | 410×320mm |

| Max moving range of Z axis | 10mm |

| Typical Mounting speed | 4000-4500cph |

| Max mounting speed | 5000 cph |

| Repeating accuracy | ±0.06mm |

| Position | Visional Position |

| Component available | SMD capacitor and resistor 0603 and IC (below 20mm) |

| Programme | Video study/ Keyboard input |

| Driving method | Use industrial synchronously driving belt |

| Belt feeder | Feeder 8mm, 12mm, 16mm, 24mm optional |

| Feeder number | 1. 24 pcs of 8MM GFTA-08S at left side 2. 22 pcs of 8MM GFTA-08S at right side (when no IC tray) |

| IC tray num | 1 at most, in the situation, TP300V just can place 24 pcs of 8MM GFTA-08S feeder |

| Operation system | WINDOWS XP |

| Compressed air | 80psi(0.5Mpa), air flow 80L/M |

| Power supply | 220v, 50Hz, 2kW |

| Weight | 350kg |

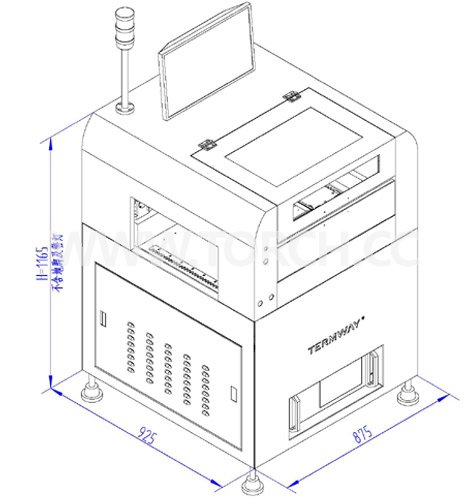

| Dimension | 780×850×1200mm |