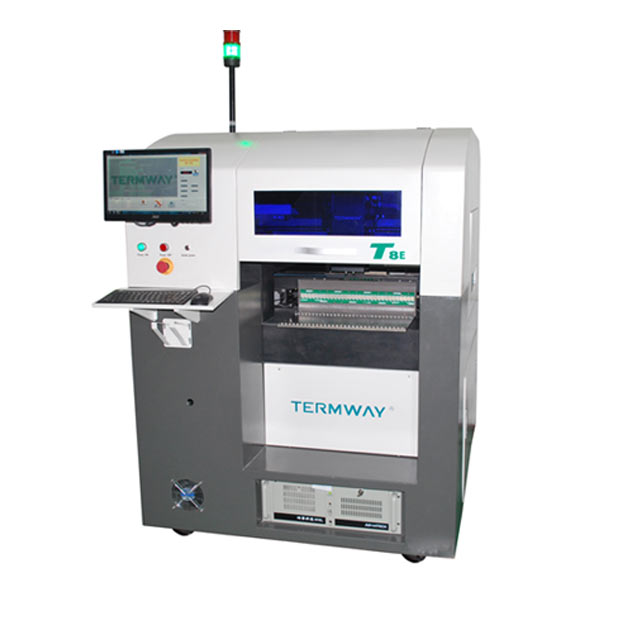

Middle Speed Multiple-function Visual Mounter Type: M6D

- Product Description

M6 Introduction:

1. High speed: Typical speed can up to;12000-14000cph. Theoretical Max mount speed can up to: 9000-11000CPH.

2. Mounter head quantity: 12

3. Integrated design of Natural granite. make sure use many years without any effect on moving precision.

4. The max mounting size: 600*450mm large PCB.

5. Moving parts configured rotary encoder, improve placement accuracy

M6D universal characters:

1. Using imported precision square rail, effectively improve the placement accuracy

2. Using a unique high-definition optical prism industrial cameras to complete mount high-precision components.

3. With the vision position system, can automatically identify the MARK point, effectively improve SMT production efficiency and placement accuracy.

4. With off-line programming function (optional, school can standard)

5. With the shortest path optimization (optional, standard schools).

6. with anti-wrong feeding system (optional, standard schools)

7. Programming is simple, easy to learn for beginners and it is convenient and practical. It can universally import the PCB data, it is most suitable for mass production in middle scale.

8. The whole machine can mount at most 2 kinds of IC trays at one time.

9. The whole machine configures a professional circuit board transmission system, seamlessly connected screen printing machine, connected to Taiwan and reflow.

10. Pick up components failed,the machine have alarm.

11. Machine has shut warning function, it can be done unattended when mass production.

12. Machine configures 12 nozzles.

T6S key configuration:

1. Industrial camera: 4 Group

2. Industrial Light Source: 4 groups

3. Industrial PC: 1 set

4. Rotary encoders: 3

5. The nozzle 12

6. Feeder chassis group GFTB-19 2

T6S Options:

1. 8mm, 12mm, 16mm, 24mm, 32mm automatic electric feeder

2. a variety of nozzle

3. Industrial pump mute

4. UPS uninterrupted power supply

5. IC tray

6. Special devices dedicated optical lens

7. Special light special components

8. Off-line programming system

9. The shortest path optimization system

10. Error proofing material system

11. Three-dimensional simulation teaching video

12. A full set of video training materials

- Technical Data Sheet

Technical Parameters:

| 1 | A number of heads | 12 titles affixed group |

| 2 | mounting area | 600mm×450mm |

| 3 | Z-axis maximum movement range | 20mm |

| 4 | Maximum speed (full visual) | 9000-11000cph |

| 5 | Maximum speed patch (non-visual) | 12000-14000cph |

| 6 | XY axis resolution Accuracy | ±0.01mm |

| 7 | Repeat placement accuracy | ±0.05mm |

| 8 | Alignment manner | Vision Alignment |

| 9 | You can mount components | 0402 above resistance-capacitance and various pieces of LED chip, while meeting the diode Transistor SOP SOT PLCC QFP, BGA and other chips mount |

| 10 | Programming method | Universal Automatic data / Import image study / keyboard input |

| 11 | Number of feeders | MAX 44 kinds CFTA-08 feeder (600mm × 450mm) (standard); MAX 38 kinds GFTA-08 feeder (600mm × 450mm) (standard); MAX 66 kinds GFTA-08 feeder (600mm × 250mm); (optional) MAX 78 kinds CFTA-08 feeder (600mm × 250mm); (optional) MAX38 kinds GFTA-08 feeder +2 species IC plate (600mm × 250mm); (optional) |

| 12 | operating system | WINDOWS XP, WIN7 |

| 13 | Compressed air | 80psi (0.5Mpa, Gas flow≥200L/M) |

| 14 | power | 220V, 50Hz, 2kW |

| 15 | weight | 450kg |

| 16 | Overall size | 1450(L)×1000(W)×1300(H) |