Middle-speed Automatic Visual Pick and Place Machine

- Product Description

1. The only one high precision pick and place machine that standard configuration can mount 0201 components.

2. The max size of QFP: 48*48mm

3. It can mount above 0.4mm pitch QFP, also can mount BGA.

4. Configure the world famous grating ruler, achieving high precision motion control.

5. The Used SMT's killer, seckill all kinds of used SMT.

- Technical Data Sheet

T4 unique feature

The only one high precision pick and place machine that standard configuration can mount 0201 components.

The max size of QFP: 48*48mm

It can mount above 0.4mm pitch QFP, also can mount BGA.

Configure the world famous grating ruler, achieving high precision motion control.

The Used SMT's killer, seckill all kinds of used SMT.

T4 general characteristics

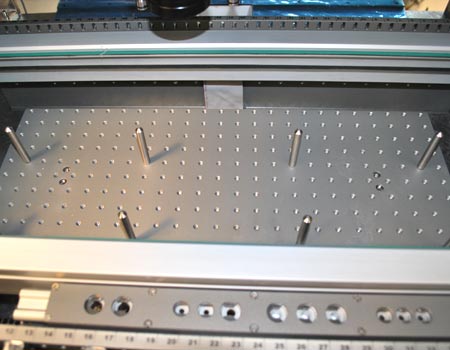

1. The whole structure is made of cast + marble platform. The bottom of the high-level marble platform; X, Y-axis gantry structure, X-axis beam using the casting process, Y-axis gantry marble structure with marble platform integration, effectively guarantee the reliability and stability of long-term use Mounter.

2. Using imported precision square rail, effectively improve the placement accuracy.

3. Using a unique high-definition optical prism industrial cameras to complete mount high-precision components.

4. With the vision position system, can automatically identify the MARK point, effectively improve SMT production efficiency and placement accuracy.

5. Automatic visional programming, it is no need to input the coordinates of components by manual, programming is simple, easy to learn for beginners and it is convenient and practical. It can universally import the PCB data, it is most suitable for mass production in middle scale.

6. Standard configure a set of minitype IC tray.

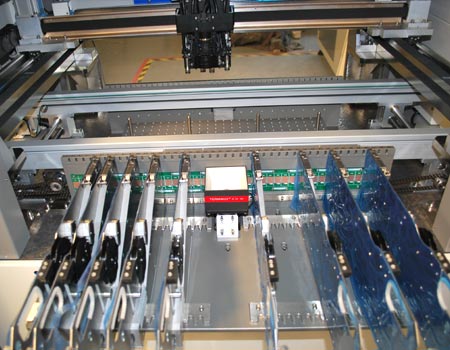

7. The placement configure 8 nozzles.

8. Cost-effective automatic placement machine, it is most suitable for mass production in middle scale and scientific research, military industrial enterprises high quality usage.

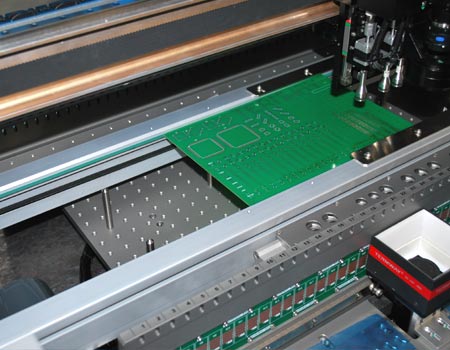

9. The placement configure a set of PCB board transport system, it can seamless connection with stencil printer, handplace desk and reflow oven.

10. Standard configuration of automatic nozzle replacement system, it can freely change 7 different nozzles.

Optional part

1. 8mm, 12mm, 16mm,24 and 32mm automatic feeder of GF type

2. Nozzle(7 nozzles, you can customize different nozzles)

3. QS48 component(mount 48*48mm IC)

4. Bulk trays

5. IC trays

6. Vibration feeder

M6 Technical parameters

| T4 | |

| Mounter head | 4 heads |

| Max PCB board | 580×230mm |

| Max move range | 640×460mm |

| Z axis move range | 20mm |

| Typical speed | Without vision: 6000-8000cph with vision: 4000-6000cph |

| Max speed | 8000cph |

| X,Y axisprecision | +/- 0.001mm |

| Repeat mount precision | ±0.015mm |

| Position manner | Visional position |

| Component available | Above 0201 and less than 38 mm IC (48mm camera and lens are selected) |

| Programme method | Automatic data import / video learning / keyboard input |

| Transmission | XY-axis high precision ball screw with precision guide+ Industrial dual-belt drive+ grating ruler position |

| Tape feeder | Optional 8mm, 12mm, 16mm, 24mm, 32mm, 44mm feeder |

| Feeder No. | Can be put 70 pcs of 8MM GFTA-08S feeder, the front and back can be put 35pcs 8mm GFTA-08S feeder (no IC tray)Can be put 80 pcs of 8MM CF feeder |

| IC feeder NO. | No more than 2 pcs |

| Operation system | WINDOWS XP/win7(32bit) |

| Compressed air | 80psi(0.5Mpa), flue 80L/min |

| Power | 220V,50Hz, 5kW |

| Weight | 700Kg |

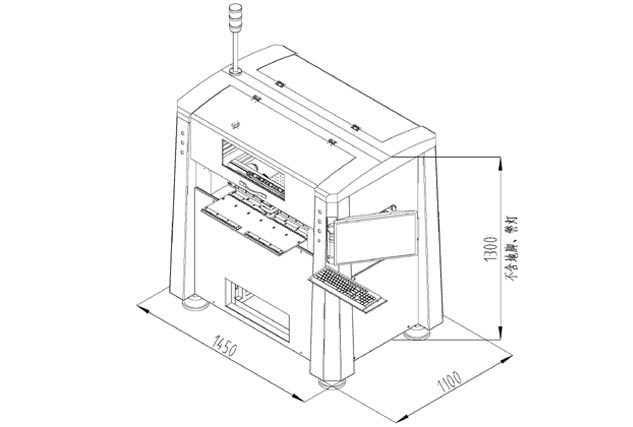

| Dimension | 1450 × 1100 × 1300mm |

T4 appearance dimensional map: