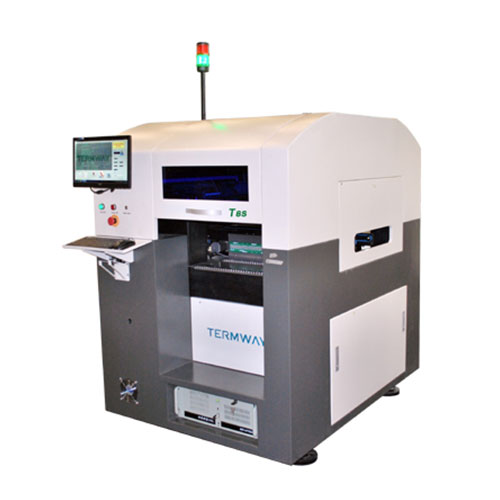

Automatic High Speed Vision Mounter TP50V6

- Product Description

TP series is a fully automatic vision SMT pick and place machine, it can mount a variety of components through the vacuum nozzle. it is the most cost effective automatic placement equipment on recently market. This machine is suit for most of the SMD components, such as 0402, SOIC, PLCC and QFP IC; With the vision position system, meet the needs of mounting high precision 0.5mm of QFP IC or BGA. Beside the standard circle reference point, the square, which is not the PCB solder paste screen printing pad ring perforated pad, can also be as a reference point to know.

- Technical Data Sheet

Introduction

TP series is a fully automatic vision SMT pick and place machine, it can mount a variety of components through the vacuum nozzle. it is the most cost effective automatic placement equipment on recently market. This machine is suit for most of the SMD components, such as 0402, SOIC, PLCC and QFP IC; With the vision position system, meet the needs of mounting high precision 0.5mm of QFP IC or BGA. Beside the standard circle reference point, the square, which is not the PCB solder paste screen printing pad ring perforated pad, can also be as a reference point to know.

Remark

1.Using imported precision square rail, effectively improve the placement accuracy.

2. Using a unique high-definition optical prism industrial cameras, high precision components to complete visual counterpoint mount.

3. With the vision position system, can automatically identify the MARK point, effectively improve SMT production efficiency and placement accuracy.

4. Automatic visional programming, it is no need to input the coordinates of components by hand, programming is simple, easy to learn for beginners and it is convenient and practical.

5. Standard configuration of automatic nozzle replacement system.

6. High Cost-effective automatic placement machine, it is most suitable for mass production of middle scale

7. Standard configuration: 3 sets vision alignment system, a set of 46 groups feeder + 6 high speed feeding chassis

Optional part

1. Automatic feeder

2. IC bowl feeder

3. Nozzle

4. Second MARK alignment system

5. AQ38 bottom mirror system

Technical Parameters:

| Max circuit board size | 600×300mm |

| Max moving size | 670×620mm |

| Max range of z-axi moving | 30mm |

| Max Speed of mounting | 6000-10000cph |

| Mounting precision | ±0.04mm |

| Position way | Vision position/ Mechanical position |

| Mounting component | Above 0402 RC parts and less than30mm pitch, more than 0.5mm IC |

| Program method | Automatic data import / video learning / keyboard input |

| Transmission | XY-axis high precision ball screw with precision guide |

| Belt feeder | Optional 8mm, 12mm, 16mm, 24mm feeder |

| Quantity of feeder | can max place 96 8MM GFTA-08S feeder, front and back each 46 front place 12 adjustable feeders, reaching take place at the same time, back place 46 feeders, totally 58 feeders |

| Quantity of IC dick | No more than 2 pcs |

| Operation system | WINDOWS XP |

| Compressed air | 80psi (0.5Mpa, flue beyond 150L/min) |

| Power supply | 220V, 50Hz, 4.5kW |

| weight | 680Kg |

| size | 1300 × 1300 × 1500mm |