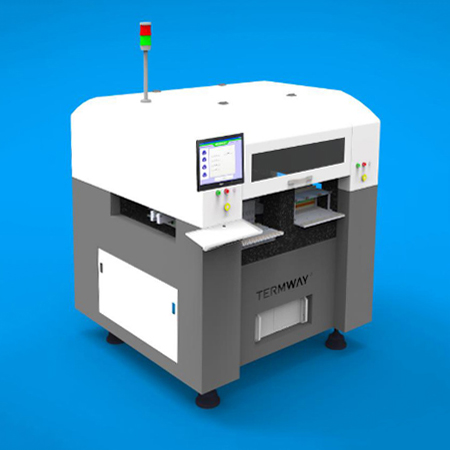

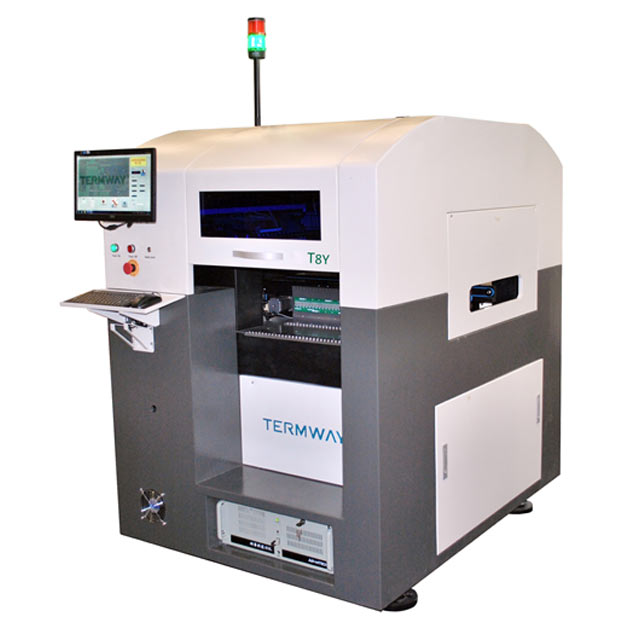

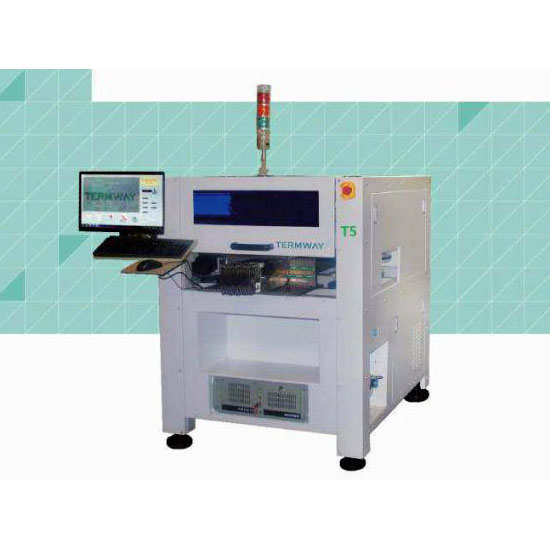

Submicron Adhesive Tape Machine/Placement Machine T8W/T8WS

- Introduction:

1. Achieve dispensing, viscose, sticky film, placement, wafer sticky, inverted packaging, GaAs, adhesive pressure control, high precision.

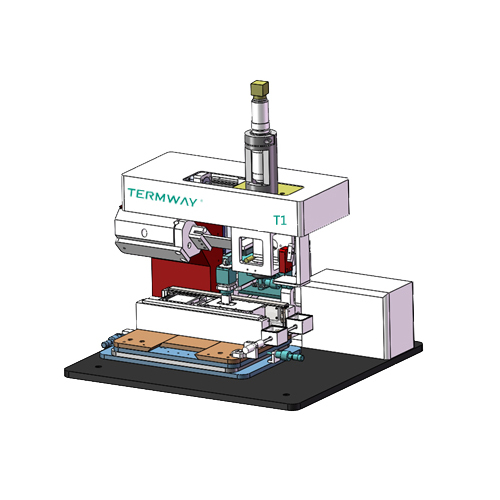

2. Use ultra-precision air movement platform, the main system X, Y axis use a high-resolution linear encoder with zero pressure, completely non-contact frictionless air float system. Encoder scale can reach to 0.02μm accuracy, can achieve high-speed, precision, sub-micron-level positioning.

3. The platform design use granite integrated high-speed sports platform of high stability, so that T8W in ensuring thermal stability and mechanical stability and achieve high-speed start time and ± 1.5μm and even better patch accuracy at the same time, so as to meet the high precision application requirements.

4. Box or disc feed: Holds up to 90 2 "x2" waffles or 24 4 "x4" cartons or combination tray.

5. Wafer for material: can support up to 8-inch wafers, equipped with a motor drive Z-axis thimble mechanical device and solid crystal ring.

6. Vacuum eutectic furnace: use infrared or plate heating, heating up quickly, but the red, and with a fast heating heater; up to 450 ℃, vacuum according to the optional vacuum pump, between 10-4pa-500pa. The temperature is programmed with a programmable temperature controller.

Function introduction:

1. Large, freely configurable work area: Top-mounted frame design provides a large work space. The system can reclaimer from any combination of waffle plates, wafer feeders and belt feeders. When Wafer reclaiming, the system uses a motor-driven, pressure-controlled lifting mechanism to pick up thin chip and large aspect ratio of the chip, and can do precision compensation. The ink dot recognition and wafer mapping function ensures that only pick up known good chips. 700 square inches of work area can easily accommodate combination of a variety of feeding and discharge methods. When use the system-specific IC disc feeder, T8W can accommodate up to 90 waffles.

2. For pressure control of high-end assembly: The T8W is equipped with a closed-loop pressure feedback function to handle gallium arsenide (GaAs) and indium phosphide (InP) devices and fragile devices and Fragile device such as MEMS. Chip release force can be as low as 10 grams, so fragile microstructure like the air bridge will not be destroyed. Each pressure of placement through the programming control, so the pick and place of each chip are under the pressure of the programming control to help ensure the consistency of solder paste or adhesive layer thickness.

3. Material delivery: The T8W is well suited to meet the requirements of specialized mass production and has the flexibility to adapt to small batch production. It can be configured as stand-alone production, use material box to material box material delivery, and also can contact with other processing equipment.

4. Tool changing - toolbox or placement head: T8W has a 15-position tool holder that can quickly and automatically replace the tool head. Can add tool replacement warehouse to achieve a larger toolbox capacity. T8W can also be equipped with four placement head. The pressure of each tool head can be controlled independently by direct feedback.

5. Advanced image positioning and visual systems: Advanced vision system can quickly detection and positioning of chips in the full range, And have strong substrate and base point calibration capability. The calibration of chips such as MMICs and beam lead diode of high requirments for orientation become possible. Vision system according to relative position of substrate and base point, chip edge or placement of the chip feature points before to calibrate and place the chip. lt ensure that repeat precision and accuracy of the contraposition of the optical and microwave devices. lt adopts border recognition or graphic recognition by application features of locate the chip center, edge or key. The quick positioning function allows chips such as MMICs and lasers to be machined directly without any pre-positioning. Global and local visual calibration functions are used for embedded substrates and signature calibration. So that the complex assembly of the processing fast and accurate. The top and bottom cameras of the T8W vision system have multiple magnifications and are equipped with light source programmed. The T8W uses a bottom camera for flip chip and other parts production with bottom features.

6. Programmable multi-color background lighting: The light intensity of each camera's circular and coaxial light can be programmed and adjusted to determine the appropriate light source for chip alignment and identification. Multi-color background light can be used to handle any materials in wide range. The red-green-blue programmable light source (optional) provides a greater ability for calibration surfaces of processing challenges, such as gold wires on alumina ceramics. The powerful visual system ensures that the production will not be interrupted by calibration errors.

7. Vacuum eutectic welding function: T8W can optional vacuum eutectic welding function. T8W supports a variety of eutectic processes, including gold-silicon, gold-tin and gold-germanium. The functions include high speed, closed loop, heating reflow oven of heating and warming up, eutectic furnace programmable to meet your eutectic process requirements, heating rate can be controlled by program make the eutectic reliability of the parts higher at the same time to avoid the thermal shock. The T8W also supports direct eutectic and reflow eutectic and with controlled contact pressure and programmable positive and negative pressure regulation. Preheat system can be equipped with nitrogen protection and hydrogen and nitrogen mixed gas protection, to prevent the work piece and substrate oxidation. The system automatically transfers the substrate or package to the vacuum eutectic furnace to complete the vacuum eutectic function. In addition to encapsulating high-power devices such as amplifiers, these features of the T8W can also be applied to mass production of optical components on optical devices such as eutectic welding on substrates such as substrates, TO shells and butterfly packages.

8. Solder paste printing and dispensing with laser distance measurement: The device can be equipped with precision dispensing controller and precision solder paste printing controller used for dispensing conductive and insulated epoxy resin, precision laser height range finder, and dispensing needle for automatic positioning and cleaning to ensure high precision dispensing or area fill. Through high-precision laser height detection, T8W achieve an unparalleled precision dispensing function. Each calibration is determined by the height of the laser to determine the slope of each dispensing surface.

9. Powerful control system and off-line programming system : The T8W Windows-based intuitive graphical user interface simplifies setup and production processes. The software system contains a set of program libraries for waffle and chips pre-programmed, and its parts are easy to learn and all substrate programs can be used. XML-formatted databases simplify data manipulation and offline programming. New visual tools, such as adjustable target areas, enhanced gain control, filters and graphics matching, enable visualization process of challenging substrate and chip materials. The CAD download function, the advanced calibration program, the function of the automatic calling program according to the QR code of the feed tray, the complete material retrospective function and the networking function, etc., It means that it seems not spend time on the program, thus optimizing the production efficiency and Equipment utilization. T8W control platform achieves smoother and more sophisticated control via motion system based on bus control and driver of all axes (including conveyor belts). The computer hardware is equipped with a front-end USB interface for easy application, and and have backup features. Dual hard drive guarantees data security and shorter downtime and faster data recovery.

10. Real turnkey works: TERMWAY offers a complete range of solutions for high-end packaging, including high-speed precision placement machines, silver paste dispensers, solder paste jet printers, epoxy dispensers and a series of products. The SMEMA compatible interface allows T8W to be integrated with a wide range of equipment including a wire-inverting vacuum reflow oven, resulting in a turnkey production solution. TERMWAY highly reliable system and localized technical service support commitment means that your device will always be able to meet production needs.

| Model | T8WS | T8W |

| X/Y movement | 500*500mm | 650*650mm |

| Encoder | 50nm or20μm fundamental | 50nm or20μm fundamental |

| Resolution | 20nm | 20nm |

| Placement speed | 6500UPH | 6500UPH |

| Flip Chip Mounting Speed | 2000UPH | 2000UPH |

| positioning accuracy | +/-lμm | +/-lμm |

| Repeat positioning accuracy | +/-0.2μm | +/-0.3μm |

| Straightness | +/-lμm | +/-lμm |

| Flatness | +/-lμm | +/-l.5μm |

| Placement accuracy | <lμm True radial positioning (up to application) | <3μm True radial positioning (up to application) |

| Repeat placement accuracy | ±lμm@3sigma | ±lμm@3sigma |

| Maximum speed | 1000m/s or 40inch/second | 1000m/s or 40inch/second |

| Maximum acceleration | 2G | 2G |

| Z-axis placement | According to the pressure or height | According to the pressure or height |

| Pressure control | Each time the placement is programmed by real-time feedback | |

| control, the pressure range is 10 to 2000 grams | ||

| Z axis movement and resolution | 45mm/0.1um | |

| Angle replacement accuracy | O.1°@3sigma | |

| Motion platform | High precision air floating solid granite platform, no cantilever parts | |

| Motion system | Imported motion control cards and encoders | |

| Tape with feed | 8mm, l2mm, 16mm, 24mm, 32mm, 44mm, can be installed up to 32 8mm feeder | |

| Chip size | minimum 0.15-5mm, replace the tip, the largest chip without the actual limit | |

| Chip thickness | Chip or welding pieces of 0.05-2mm thick | |

| weight | 2000kg | 2100kg |

| Dimension | 1730(L) x l400(W) x 1480(H) | 1880(L) x l400(W) x 1480(H) |