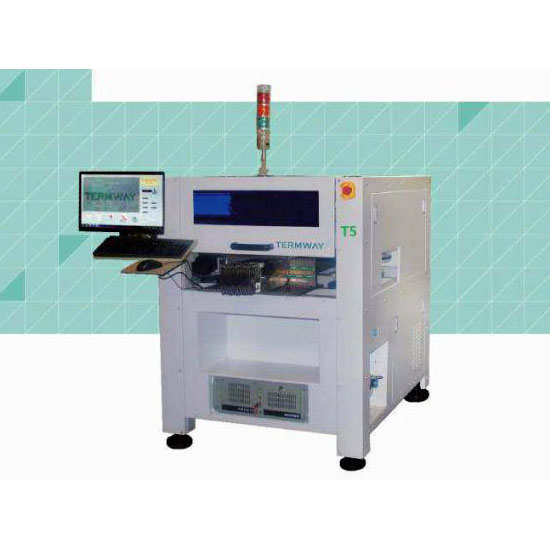

Multifunctional Bulk Placement Machine T5S

- Introduction:

T5 is the most cost-effective bulk automatic placement machine in the market. It is the first placement machine for small and medium-sized enterprises, R & D centers, military enterprises and research institutes. Reliable mounting of components above 0201, meeting the requirements of high precision IC mounting.

Features:

1. The world's first multi-functional bulk placement machine that can automatically mount bulk materials, short tape materials and braided tape materials. Meet the requirements of the automatic placement of bulk materials after the detection and screening of incoming materials; It can meet the automatic placement of short tape and half cut material.

2. The function of automatic picking, automatic identification, automatic alignment and automatic mounting of bulk materials (randomly placed bulk materials) can be realized.

3. It has the function of off-line feeding, and can carry out bulk feeding in the off-line state.

4. A variety of feeding methods, support bulk material, short tape material, braided tape material, tubular material, IC disk loading.

5. The state of bulk material is determined by the patented technology visual identification system.

6. Equipped with imported servo motor, it can realize high precision motion control and high precision repeat mounting of the whole machine.

7. The whole machine adopts German original high-definition first-class industrial camera and high-quality lens to ensure the high precision and accuracy of visual alignment, and complete the visual alignment mounting of high-precision components.

8. Equipped with automatic nozzle changing system, 6 different sizes of nozzles can be changed freely.

Options:

Visual recognition of bulk materials

1. GF electricity move feed material Instrument (8mm, 12mm, 16mm, 24mm, 32mm, 44mm).

2. Suction nozzle (6 kinds of suction nozzles, can accept customized suction nozzle of special-shaped parts)

3. Qs48 module (can mount 48 * 48mm IC)

4. 1 set of standard bulk material tray

5. IC tray 2 groups

6. Short belt feeder

7. Vibration feeder

Technical Parameter:

| 1 | Mounter head | 1 |

| 2 | Typical mounting speed | 1000-1500CPH (bulk material), 2000-3000CP (short tape, braid) |

| 3 | Mounting area | 300*300mm |

| 4 | Mounting device height | 15mm |

| 5 | Motion System | XY Japanese Panasonic servo motor driver + high-precision industrial screw guide |

| 6 | XY axis precision | ±0.001mm |

| 7 | Repeat Placement Accuracy | ±0.02mm |

| 8 | Position way | Visual Position |

| 9 | Component available | Component in inch size 0402(bulk material) resistors and size of IC less than 40mm*40mm |

| 10 | Programming method | Universal data automatic/import image learning/keyboard input/offline programming function |

| 11 | Feeding method and quantity | 1. 32 pieces / group of GF-8 feeders, up to 32 kinds of 8mm GFTA-08S feeders. 2. 60 pieces / group, a total of 60 kinds of bulk materials. 3. 4 pieces / group * 6 groups, a total of 24 kinds of 8mm short tape materials. 4. 1 IC tray (standard configuration). |

| 12 | Vision registration camera | 2 groups |

| 13 | Mark Camara | 1 group |

| 14 | Operation system | WINDOWS XP, WIN7 |

| 15 | Compressed air | 80Psi (0.5Mpa), gas flow rate 80L/M |

| 16 | Power | 220V, 50Hz |

| 17 | Weight | 680Kg |

T5S equipment configuration:

| Item | Qty |

| T5S Industrial computer | 1 |

| Short strip material | 10 |

| 8mmelectric feeder | 10 |

| 12mmelectric feeder | 3 |

| 16mmelectric feeder | 3 |

| bulk components | 30 kinds/big plates |

| Deep cavity nozzle | 5 |

| IC tray | 2 |

| Short strip material tray | 1 |