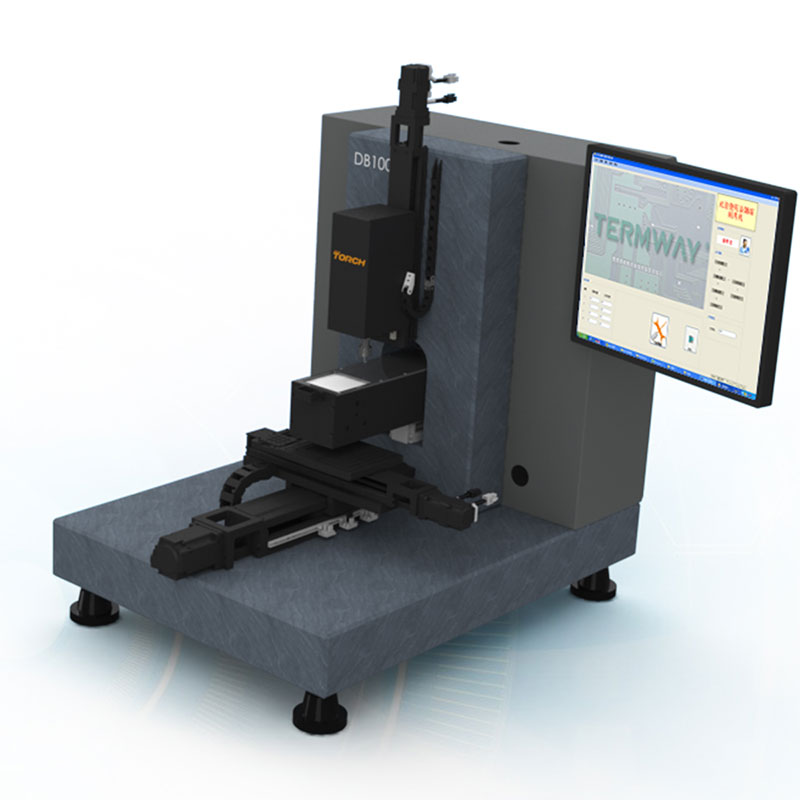

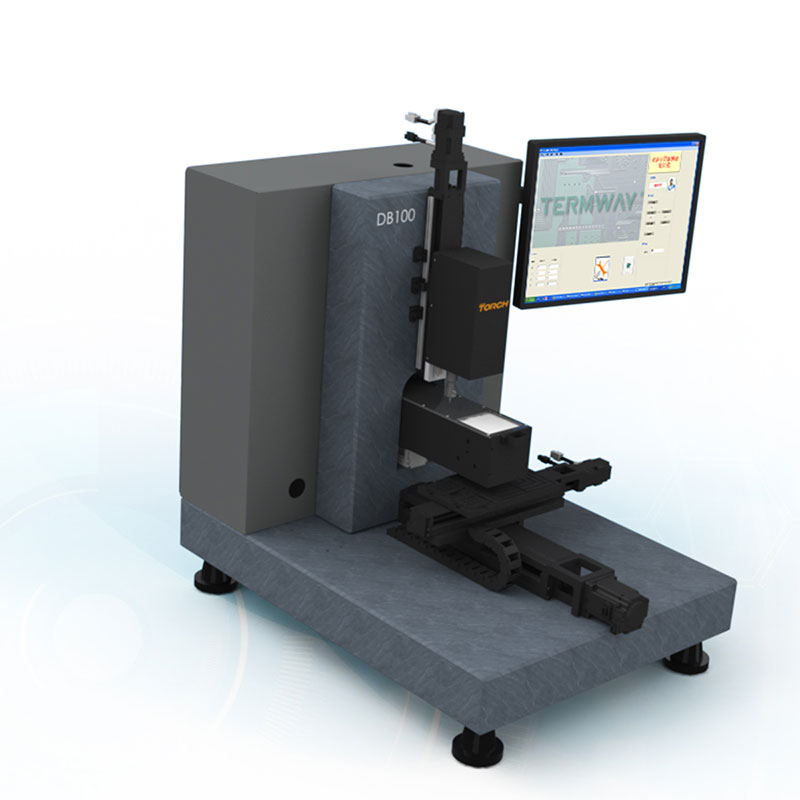

DB100 Series High Precision Die Bonder

- Introduction:

DB100 is a manual-semi-automatic micro assembly placement system. The whole machine uses a marble motion platform to ensure that the entire motion accuracy reaches the sub-micron level. It comes with a laser height measurement system, which can meet the needs of deep cavity substrate patch and eutectic welding. Optional module: nozzle heating module, nozzle pressure feedback system, UV dispensing and curing module, nitrogen protective gas module, substrate preheating module, process monitoring module, chip flip placing module.

The placement accuracy of the system can reach 1um according to different configurations, and the nozzles can be manually replaced according to different sizes of chips. It is a necessary equipment for high-precision adhesive bonding of high-end medical equipment (core imaging module assembly), optical devices (laser LD Beijing Torch CO., LTD Add: 12I factory building, No 15, Jingsheng South 4th Street, Jinqiao Science and Technology industrial base, Zhongguancun High-Tech Park, Tongzhou District, Beijing Web: www.torchsmt.com www.termway.com Tel: 86-010-84335963-890/891/892,Fax: 010-51662451-8001 palladium bar assembly, VCSEL, PD, LENS, etc.), semiconductor chips (MEMS devices, radio frequency devices, microwave devices, and hybrid circuits). It is pretty suitable for the R&D and the needs of small batch and multi-variety production of research institutes, military units, universities and other research institutions, enterprise laboratories. The machine has high precision, stable performance and high cost performance. The operation is very convenient, especially suitable for high-precision chip assembly.

Technical Parameter:

| Model | DB100 | DB100S |

| Max. chip size | ≤20mmx20mm (50*50mm optional) | |

| Min. chip size | 0.2×0.2mm | 0.2×0.2mm |

| Mounting precision | ±3um 3δ | ±3um 3δ |

| Feeding mode | 2 inch waffle box*2 | 2 inch waffle box*2 |

| Maximum nozzle pressure | Maximum 200N, minimum 2N | Maximum 200N, minimum 2N |

| X Y Z axis motion system | Roller screw + servo motor | Roller screw + servo motor + grating ruler |

| X Y axis resolution | 0.1um | 0.1um |

| Z-axis resolution | 0.1um | 0.1um |

| R axis θ axis angle | Rotation control accuracy: 0.01° | Rotation control accuracy: 0.01° |

| Air supply | Industrial diaphragm pump | Industrial diaphragm pump |

| Power | 3KW (not including eutectic table) | 3KW (not including eutectic table) |

| Power supply | 220V, 50Hz | 220V, 50Hz |

| Net weight | 150Kg | 160Kg |

| Dimensions | 800 * 750 * 630mm | 800 * 750 * 630mm |

Standard configuration:

1. Placement system.

2. Visual calibration system (systematic inspection and calibration of the precision of the mounted chip).

3. Laser ranging system.

4. Dipping glue system.

5. High-precision visual alignment system.

6. Servo motion control system

Optional accessories:

1. Top nozzle heating module.

2. Nozzle pressure feedback system.

3. Dispensing and UV curing module.

4. Nitrogen protection gas module.

5. Substrate preheating module.

6. Eutectic platform.

7. Chip flip placing module