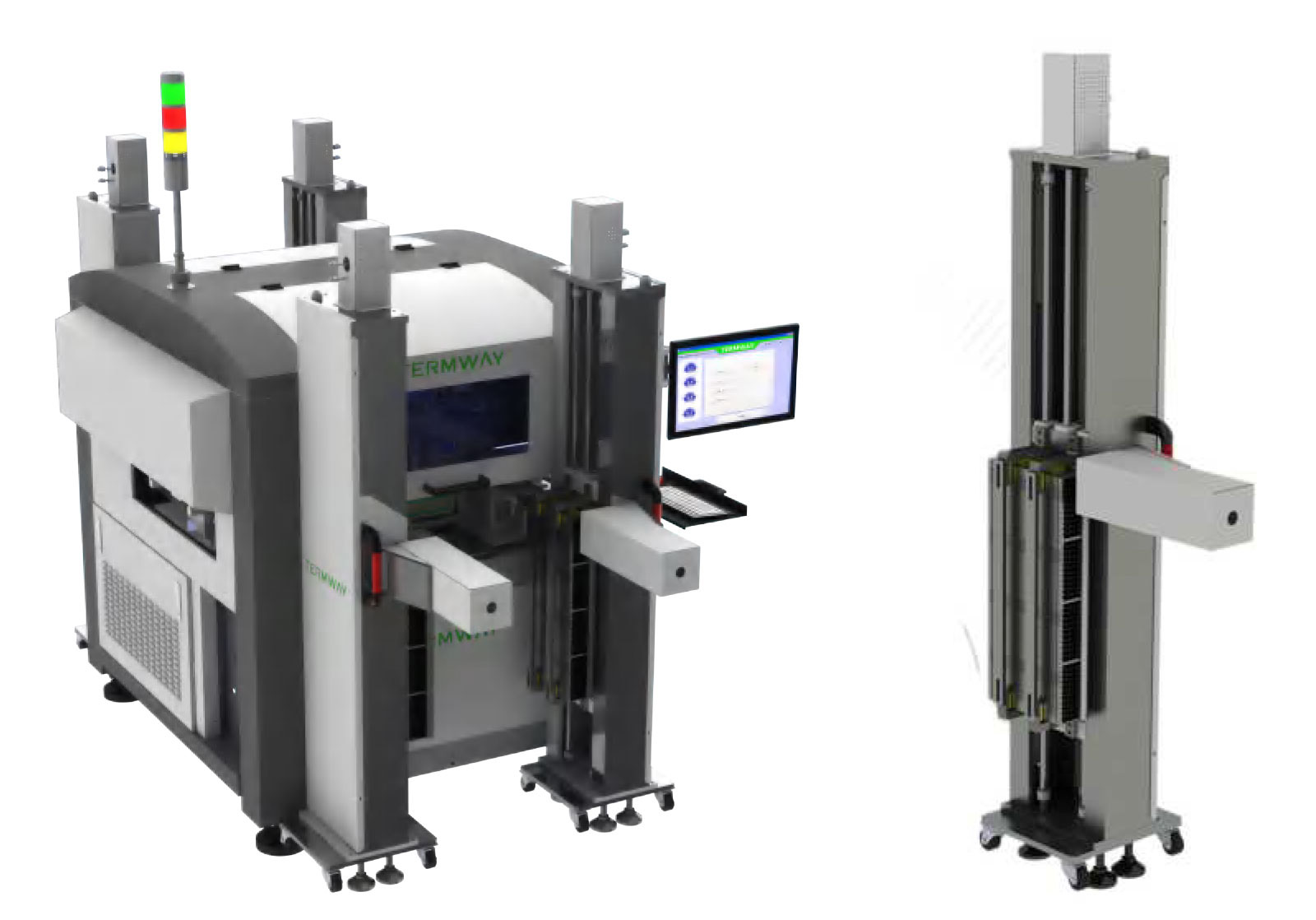

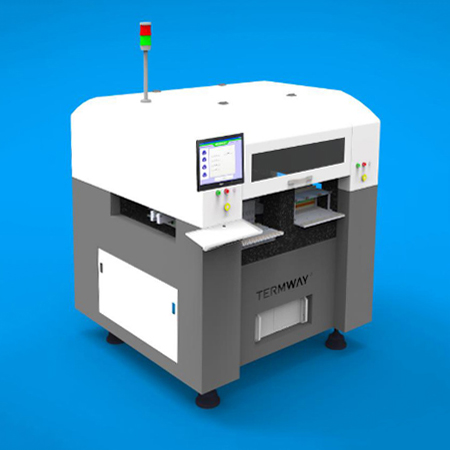

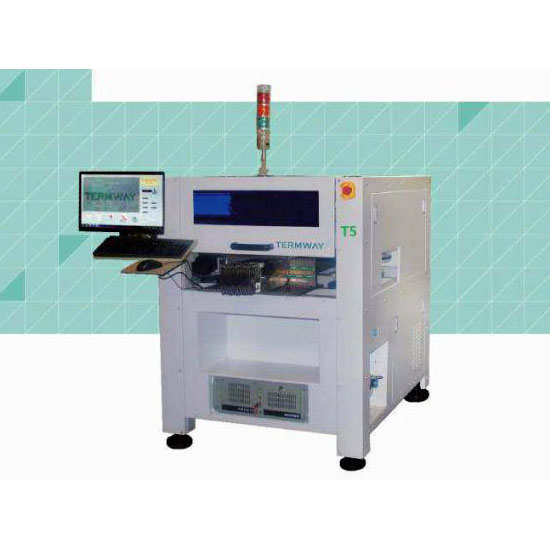

Automatic Epoxy Bulk Components Mounter T6/T6PLUS

T6/T6PLUS Introduction:

The special full-automatic placement machine for bulk components can install various components through the vacuum suction nozzle. It is an automatic placement equipment for bulk components with high cost performance in the market. It is the smart choice of bulk components mounter for small and mediumsized enterprises, R&D centers, military enterprises and research institutes. Reliable mounting 0402, 0201, equipped with visual alignment system to meet the mounting of high-precision QFP IC or BGA chips in addition to the standard circular reference point, square PCB pads and ring perforated pads without silk screen solder paste can also be identified as reference points. At the same time, the equipment has the function of glue distribution.

T6/T6PLUS Function:

1. Equipped with first-class grating ruler to realize high-precision motion control and high-precision repeated mounting of the whole machine.

2. The high-precision motion platform made of magnesium and aluminum can effectively ensure the stability of the motion accuracy of the mounter in long-term use. At the same time, the integrated structure also has very excellent seismic capacity.

3. International first-class high-speed motion system and high-precision linear guide rail are adopted to effectively improve the patch accuracy.

4. Professional industrial cameras and lenses are used to ensure the high precision and accuracy of visual alignment, and complete the visual alignment and installation of high-precision components.

5. Automatic visual programming, simple operation, convenient for beginners, convenient and practical. It can import circuit board data omnipotently.

6. The universal circuit board positioning device is convenient for the mounting of various circuits.

7. The machine has the automatic detection function of circuit board height and the alarm function of component picking failure, which can effectively improve the production quality.

8. It has electric bulk tray feeder, electric braiding feeder, pipe feeder and IC tray area. It has the pasting function of bulk components, braiding and short material belt.

9. It has the function of off-line feeding, and can carry out bulk feeding under the off-line state.

10. It has the function of CAD data import and offline programming, and can program PCB files generated by CAD software (Protel, dxrcadencezmentor graphics).

11. It has the automatic mounting function of chip bulk material elements. The picked up materials are automatically picked up and the pasted materials are automatically pasted, and the bulk materials are placed at will. At least 60 kinds of bulk components can be pasted at one time. It is equipped with 4 groups of bulk components pallets, and the configuration of charging cart can meet the mounting of 160 kinds of bulk components.

12. With automatically identifying mark points function.

13. Equipped with automatic nozzle changing system to meet the non-stop installation of different components.

Technical Parameter:

| Model | T6 | T6PLUS |

| Mounting head number | 3 groups of mounting heads + 1 groups of dispensing heads | 3 groups of mounting heads + 1 groups of dispensing heads |

| Mounting area | 550×390 mm | 290×860 mm |

| Mounting speed (CPH) | 1500-3500 | 1500-3500 |

| Mounting movement range | 730x760 mm | 743×777 mm |

| Moving system | XY axis adopts linear motor | XY axis adopts linear motor |

| Mounting alignment mode | 3 groups of visual alignment system | 6 groups of visual alignment system |

| Feeder | Up to 88pcs 8mm braid feeder | 40pcs 8mm braiding feeder |

| Number of IC trays | Up to 5pcs | 1pcs |

| Short belt feeder | Up to 40 groups of 8mm (4 material per group) | Moving feeding module: 4 groups, each group dimension: L825×W350×H1846mm It can provide automatic silo feeding system with more than 160 kinds of mounting components, which can meet the mounting requirements of multiple varieties and small batches. |

| Automatic bulk material feeding system | Up to 4 groups (15 materials per group) | |

| Nozzle changing system | 5 station | 11 station |

| Compressed air | 80psi, 0.5Mpa, Gas flow≥100L/M | 80psi, 0.5Mpa, Gas flow≥100L/M |

| Dimensions | L1900 × W1500 × H2210 mm | L3070 × W1468 × H1539 mm |