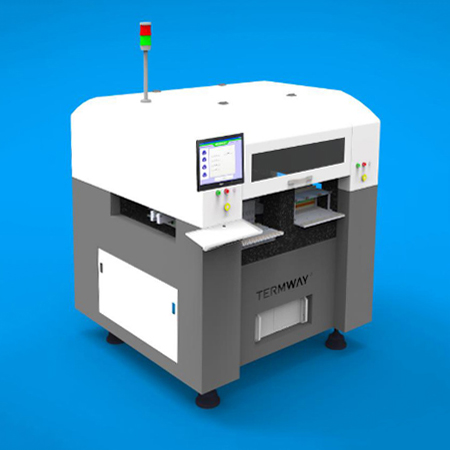

Automatic Ultrasonic Coarse Aluminum Wire Pressure Welding Machine TG3330

- Introduction:

Automatic ultrasonic coarse aluminum wire pressure welding machine TG3330 uses rotary welding head mode, adopts digital automatic frequency tracking ultrasonic system, digitally controlled pressure regulation function, first-class image recognition device and full closed-loop motion control circuit. It truly realizes the full automation of China's coarse aluminum wire bonding machine!

TG3330 is mainly used for welding 18650 Tesla batteries, 26800 lithium batteries, IGBT rapid recovery modules, automotive electronics, etc.

Advanced image recognition technology and automatic positioning technology are adopted to realize the automatic and accurate positioning of solder joints.

The powerful and abundant digital ultrasonic ensures the stable and reliable quality of solder joints. Fully automatic frequency tracking ultrasonic system and reasonable welding head design ensure the quality of welding joints.

The original digital pressure control system ensures the constant output of pressure and the consistency of solder joints.

Precise mechanical transmission mechanism, reliable industrial computer and software with independent intellectual property rights ensure the accuracy of welding position.

It has a variety of fault alarm and shutdown functions such as failure of one welding and abnormal setting out, which greatly reduces the rate of defective products and greatly improves the output. More operable and humanized.

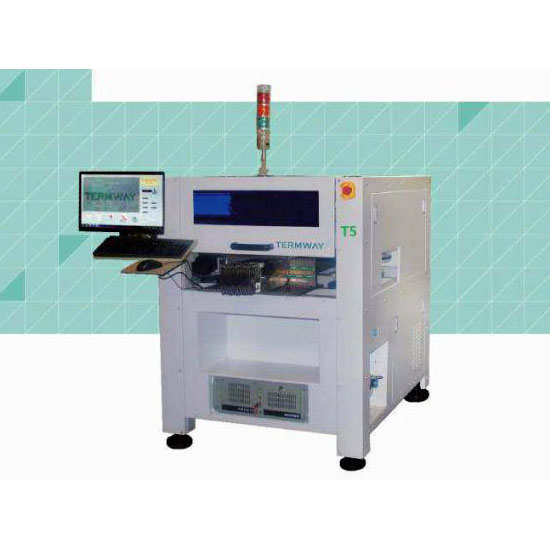

Using computer-controlled Chinese operation interface, new employees can operate by themselves in one day and skillfully in one month. One person can operate multiple machines at the same time, which greatly improves the work efficiency.

Equipment Features:

1. Manual feeding, automatic identification and positioning, automatic bonding and manual blanking.

2. This assembly machine is dedicated to the bonding production of battery products specified by customers. Non general equipment. If other products are needed, they need to be transformed and used according to the actual situation.

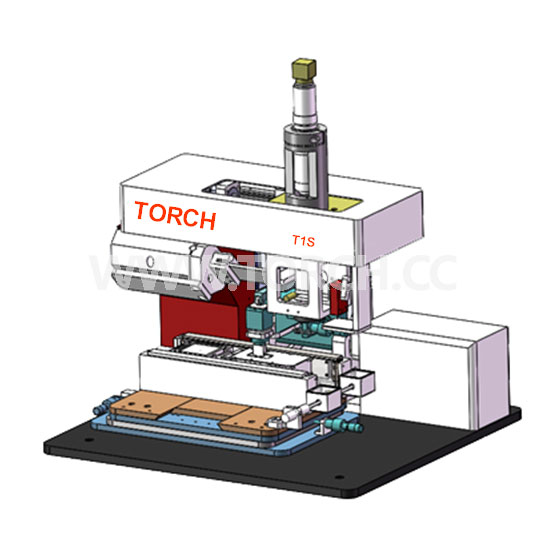

3. The machine is mainly composed of frame assembly, xyzc feeding assembly, wire feeding mechanism, fixture positioning and pressing assembly, welding head mechanism and console.

4. X adopts linear motor and YZ module adopts precision ball screw transmission. The distance repeated positioning accuracy is less than ± 0.02mm and the angle positioning accuracy is ±1°.

5. The control system adopts industrial computer + motion control card to control the operation of private server motor, with simple equipment operation and maintenance, friendly control interface and digital parameter setting; More flexible.

6. Quick clamping and single button start are adopted, which makes it easy and safe for personnel to discharge materials.

Brief description of production process:

Manually place the product on the fixture and push the quick clamp to compress the product. One handed button start.

The equipment takes photos and positions the mark points on the product through the camera.

After positioning, the moving mechanism drives the welding head for welding.

After all fuses are welded, return the welding head to the original point, manually turn the product over and continue the above steps.

After welding on both sides, blanking shall be carried out manually.

Work round and round.

Main technical specifications:

Power supply: 220VAC ± 10%, 50Hz, reliably grounded, and the maximum dissipation rate is about 800W

Ultrasonic frequency: 60KHZ

Ultrasonic power: 0 ~ 30W, automatic switching of first and second welding

The x-axis adopts linear motor - the repeated positioning accuracy can reach ± 0.02mm

Weldable aluminum wire diameter: 125 ~ 500um (5 ~ 20MIL)

Working area: XY axis Max: 200 × 250 (can be customized according to customer requirements)

Z axis: 50mm Axis C: plus or minus 90 ° Ultrasonic time: 10 ~ 500ms, multi-channel

Welding pressure: 50 ~ 1200g, multi-channel

Welding speed: about 1.5 seconds per wire (Note: different wire diameters also have an absolute relationship with the production speed; the moving distance between different batteries and the production speed will vary greatly; the welding ease and speed of materials are different.)

Welding angle: ± 90 degrees

Visual system: the magnification of PR microscope is 0.5x

PR lamp: white light, brightness adjustable

Overall dimension: About 800mm * 610mm * 1550mm (L * w * h)

Weight: About 350kg