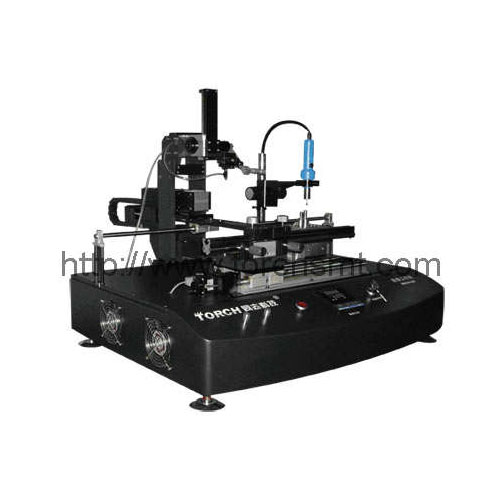

Precision Counter Soldering System BGA3200

- Technical Data Sheet

Precision Counter Soldering System BGA3200 Summarize:

BGA3200 rework table include BGA mounter system, transmission system and weld system. It used to rework and weld BGA and CSP chips. Achieve surface mounter pin and PCB surface board imaging synchronously and contraposition exactly. Accomplish BGA chips unsoldering and rewelding. It is the same with high precision component, such as QFP and PLCC.

Remark

Characteristic of mounter and transmission system:

◆ Special precision apparatus beeline trace and circumgyration flat could achieve 2μm resolving power in the range of 13mm and 2 degree exact regulation.

◆ Lambency double colour technology, red LED illuminate on chips while green on PCB surface board. The intensity of the ray could be controlled to strengthen the image contrast.

◆ Advanced optics system make sure the imaging of BGA and PCB at the same time and improve the definition of image.

◆ High definition CCD outputs PAL and VGA signals to achieve the contact of industry monitor and PC display. 50X optics magnifier make the orientation easy and accurate.

◆ Industry Diaphragm Pumps improve big size BGA mounter efficiency especially to the heavy metal encapsulation BGA.

◆ Professional nozzle has a reliable and steadly suction to pick up the chips cooperating with Industry Diaphragm Pumps.

Characteristic of weld system:

◆ Unsoldering and soldering process could be controlled automatically, and BGA soldering and remending curve will be stored in computer according to concrete demands making the remending operation conveniently. There are 40 temperature points in every curve to improve the quality.

◆ Iintelligent BGA unsolder system cooperating with bottom arm-up table improve the efficiency and prevent distortion.

◆ Test the temperature accurately according to the requirement, observe easily and control conveniently.

◆ The all-purpose worktable stand could nip different size and dfferent thickness PCB conveniently.

Planting ball worktable cooperating with BGA workstation achieve planting ball and reworking of BGA:

◆ Alloy aluminum frame, durable, light and handy.

◆ Exactly oiled axletree, and precise orientation.

◆ A planting table cooperating with different planting stencil is avaiable for different BGA.

Instriction of equipment:

1. Industry mounter rocker is more efficient than traditionals, and has the ability of automatic replacement fuction.

2. Industry high precision and four-dimensional mounter system is easy to achieve tiny adjustment.

3. Lambency double colour technology--red and green lamp-house strengthens the image contrast to achieve exact contraposition.

4. Concise design, easy opration.

5. Independently developed BGA rework table software includes BGA mounter system, transmission system and weld system. It adjust and test the curve easily.

6. Optics contraposotion system drived by the step motor laser could improve the efficiency effectively.

Parameter:

| Dimensions | 1100mm×720mm×620mm |

| Weight | About 150kg |

| Total Power | 2300W |

| Nozzle Heating | 550W |

| Bottom Warm-up | 1500W |

| Pressure | 220V (50HZ) |

| PCB Size | Max250mm*300mm, Min30mm*10mm |

| PCB Thickness | 0.5-3mm |

| Mounter Size | Max18mm*18mm, Min7mm*7mm (48mm*48mm optional) |

| Mounter Precision | 10um |

| Picking-up Power | 1.0N |

| Temperature control system | Model Kintelligent system, closed loop control |

| contraposition system | Automatic contraposition |

| contraposition &drive system | Step motor laser |

| PCB transmissiom system | Manual |

| PCB transmissiom &drive system | Precisely manual move |

| Planting ball table configuration | Optional |