Date: 2019-12-16

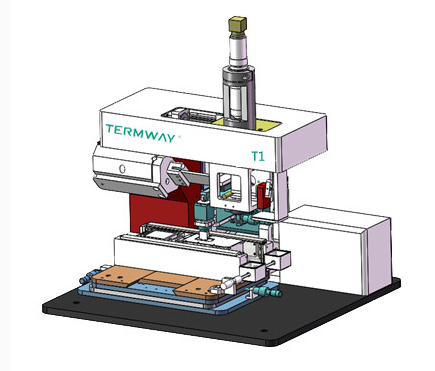

T1 is a multi-function placement machine, also a submicron flip eutectic placement machine, providing placement accuracy up to 5 microns, suitable for all kinds of flip chip, common chip mounting, can handle the minimum chip spacing as low as 50 microns.

This universal SMD platform is suitable for a wide range of microassembly applications, covering almost all microassembly SMD processes, and can even be configured as cutting-edge FC/SMD repair systems.

Mainly for small and medium volume production, and to meet the needs of prototype manufacturing, research and development and university teaching and research.

Submicron flip eutectic mounter

Application:

Flip chip bonding (face down)

High precision chip bonding (face up)

Laser diode, laser bar welding

VCSEL, PD, lens assembly package

High-end LED packaging

Micro-optics device packaging

MEMS encapsulation

Sensor package

3 d packaging

Wafer level packaging (W2W, C2W)

Chip to glass substrate, chip to flexible substrate mount

Process:

Hot pressing

Hot - ultrasound

ultrasonic

Reflux, sintering (tin, C4, indium, eutectic)

Adhesive technology

Curing (uv, temperature)

Mechanical assembly

Highlights:

Mounting accuracy: better than 5 inch m

Component dimensions: 0.125 mm x 0.125 mm - 100 mm x 100 mm*

Maximum working area: 450 mm x 122 mm*

Supported maximum wafer size: 8"

Maximum patch pressure supported: 700 N*

Can be configured as a cutting-edge hot air repair system

Manual, semi-automatic matching

Features:

Automatic process and data processing

Spectroscopic image alignment system

Process integration process management

Real-time process observation camera

Intelligent system software and adaptive library

Process transfer between different systems, covering almost all high - end interconnection process

Modular design, strong process flexibility

Advantages of submicron flip eutectic mounter:

No - hand chip mount, eliminate the influence of personnel factors

Excellent mounting accuracy, out of the box, no need to adjust

Achieve synchronous control of all process parameters: pressure, temperature, time, power, process environment, and lighting and video

Real-time observation and feedback greatly reduce process development time

Process development is simple and convenient, supporting automatic process recording

Rapid realization of the research and development process into production process

High return on investment, one platform for all process applications

Technical parameters of submicron flip eutectic mounter:

Field of view (minimum): 1.6mm*1.2mm

Field of view (maximum): 20mm*15mm

Component size (minimum) :0.125mm*.125mm

Element size (minimum) :40mm*40mm

Φ shaft fine-tuning: plus or minus 6°

Z-axis travel of the workbench: 10mm

Working area: 280mm*117mm

Heating temperature (Max.) 400

Patch pressure (Max) 700N

Modules and options:

ACF module

Module balls

Patch force control module (automatic)

Chip heating module

Blue film chip module

Camera moving module

Inert gas protection module

Process video observation module

Friction module

Substrate heating module

If you are interested in our products, please visit our website (www.torch.cc) or search Eutectic mounter on baidu to learn about our products.